See the sound: how UST Inc. engineers conduct vibroacoustic vehicle testing

One of the most significant factors influencing passenger comfort and safety is the level of noise and vibration in the cabin. These features are crucial in determining the level of comfort one will experience during the trip, the level of fatigue they will feel during the journey, and the performance of the system over time. To investigate and mitigate the adverse effects, the experts at UST Inc. perform thorough vibroacoustic tests of rolling stock and track structures of the string rail complexes.

How Can Sound Be Seen?

As a general rule, vibroacoustic testing of rolling stock is a time-consuming process. Vladimir Ovsyanko, Head of the System Dynamics Calculation Team at the Design Office for Mechanical Engineering Structure Calculations, explains:

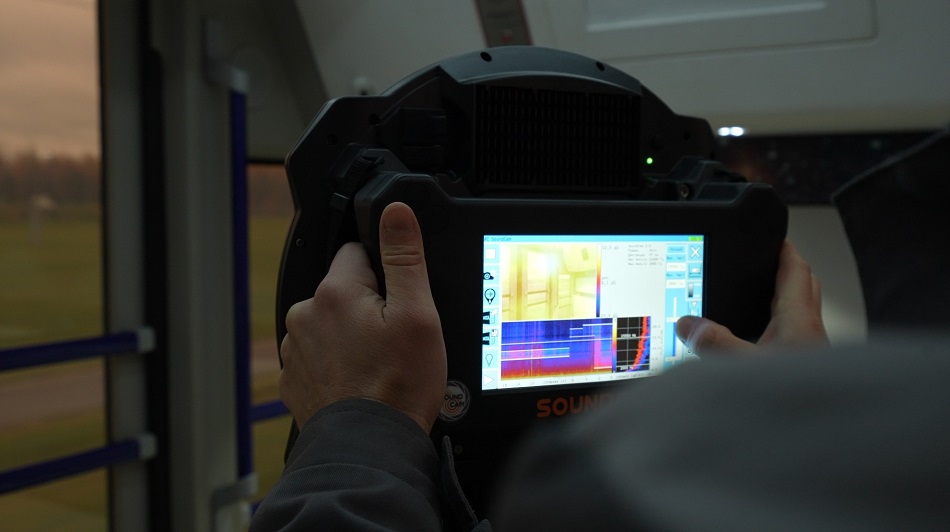

“For these tests, we use not only standard microphones but also unique equipment - an acoustic camera or acoustic array. This device allows you to literally see sound: the color visualization on the screen shows the loudest and quietest parts of the acoustic space in real-time.”

The acoustic array consists of an optical camera and 64 MEMS microphones that simultaneously process and record sound in real-time. The resulting acoustic field map shows the distribution of sound pressure levels within the uPod's interior.

While standard microphones employed in certification tests capture only the overall noise level, the acoustic array enables precise identification of the sound source's position and the trajectory it follows within the cabin.

The Path to Silence

The tests are conducted sequentially, square by square. Engineers check every part of the uPod's interior to identify areas with increased sound pressure. In this case, not only is the level of sound determined and visualized, but also its frequency spectrum. This data is then transmitted to the design and research departments, where experts analyze the causes of the vibrations and suggest ways to reduce them.

Sometimes, solutions may be unconventional and involve modifying the body's shape, reallocating the weight and stiffness of individual components, or choosing a different type of soundproofing material.

"Our goal is not simply to meet certification requirements," emphasizes Vladimir Ovsyanko. "We aim to exceed them, so that passengers feel as comfortable as possible, even when driving at high speeds."

Testing Inside and Out

All acquired data is stored and subjected to further digital processing, such as filtering, spectral analysis, and comparison with reference parameters. Nevertheless, the engineers extend their analysis beyond internal measurements.

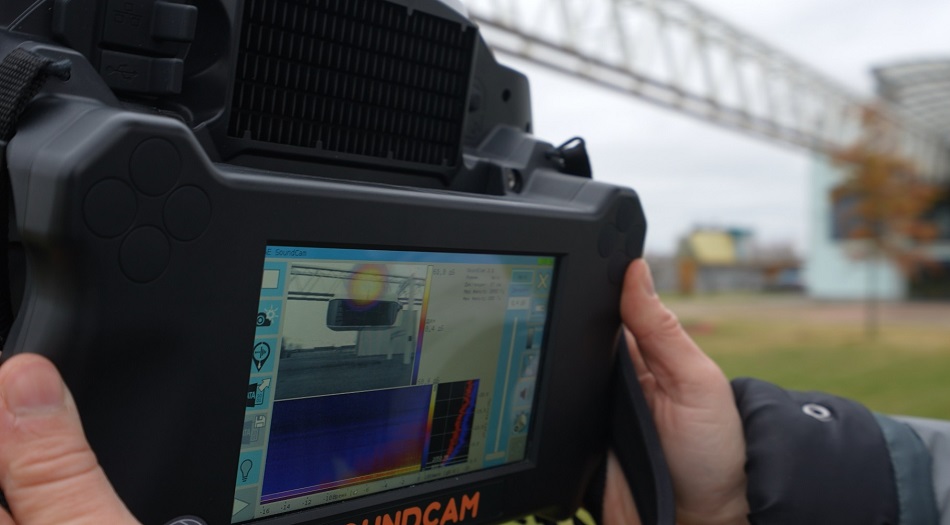

Since uST solutions are not just vehicles, but complete transport and infrastructure systems, the source of noise and vibration is not only the individual uPod, but also the entire above-ground string rail track structure.

After measurements in the cabin, specialists also conduct similar tests outside on the track, including the supporting towers and anchoring structures. This demonstrates how the interaction between rolling stock and the track affects the acoustic environment and what measures should be taken to reduce noise throughout the system.

The Technology of Comfort

The vibration and acoustic testing of uST complexes is an example of how precision engineering is combined with a focus on passenger comfort. Thanks to advanced techniques for measuring and visualizing sound, UST Inc. can now not only reduce noise, but also create a quiet environment by incorporating sound-absorbing features into the design of their vehicles. This way, the company's solutions are not only efficient and environmentally friendly, but they are also truly quiet.

More news

Blog

22 February 2023

How Can uST Solutions Be Integrated Into the Infrastructure of a Large City?

uST solutions help arrange transport communication in a large city – connect urban and suburban areas, and link distant or multi-bank parts of a megacity.

Blog

24 October 2024

How UST Inc. Solves the Challenge of Building Complexes on Terrain with Utilities

Solutions by Unitsky String Technologies Inc. seamlessly integrate into dense urban environments without disrupting existing surface transportation routes. But what about underground and aboveground utilities like water pipes and power lines?

News

15 August 2022

Unitsky String Technologies Inc. Present Updated Market Positioning

UST Inc. has published a document with updated market positioning. It contains key information about the company, describes the principle of operation and capabilities of transport and infrastructure complexes, compares with competitors, indicates the cost of construction and the timing of projects.