In 2024, the semi-rigid string rail track structure built at the uSky Center became certified by TUV SW.

The document confirms the compliance of the transport overpass with international safety and quality standards

Unitsky String Technologies Inc. develops and manufactures uST Transport & Infrastructure Complexes in accordance with international requirements, which makes it possible to adapt the company’s products to all markets in the shortest possible time.

The activity of UST Inc. is based on the principles of the international quality, environmental, health and labour safety management systems. These approaches serve the basis and the key to the successful fulfillment of all requirements to confirm compliance of uST Transport & Infrastructure Complex with the regulations

What is included

Steel-wheeled electric car

Confirmation of compliance

Confirmation of compliance in the form approved by the Regulatory (Transport, National Safety) Body of the project country

What is included

Communication, software, electric rail car control system, infrastructure control system

Confirmation of compliance

Confirmation of compliance in mandatory form for the safety functions Certification / Declaration

What is included

String rail overpass, power supply system, buildings and facilities

Confirmation of compliance

Legislation of the complex operator country in construction

Certification of any transport system, including the innovative one, comes down to the proof of safety according to national and/or international requirements of the country where the targeted project is implemented

The company has two Test & Demonstration Centers located in Belarus (Maryina Gorka) and the United Arab Emirates (Sharjah). At these centers, all technological solutions of UST Inc. undergo numerous inspections, tests, and certification. The information obtained is processed. If necessary, design and technological changes are made in the operating documents.

The location of Test & Demonstration Centers in two diametrically opposed climatic zones makes it possible to fully consider external climatic features (from frost, snowfall and ice to heat, sea salts in the air and soil, sand storms) to further implement projects anywhere in our planet

UST Inc.'s competencies are confirmed by certificates of conformity for the right to act as the general designer, for the right to develop sections of project documentation for construction projects of the first to fourth complexity categories, as well as for the right to provide engineering services in the implementation of activities in the construction of facilities of the first to fourth complexity categories

On April 20, 2022, Unitsky String Technologies Inc. was granted the status of a scientific organization. The company was accredited by the National Academy of Sciences of Belarus and the State Committee for Science and Technology, after which it received the appropriate certificate. At that time, Unitsky String Technologies Inc. became the 8th private company in Belarus to gain such a status

Unitsky String Technologies Inc. is a reliable and conscientious partner for business activities both in Belarus and abroad. Another confirmation of this is the inclusion of the company in the relevant register of business entities by the Belarusian Chamber of Commerce and Industry

TUV SW is an organization providing solutions in the field of quality, safety and sustainable development, specializing in testing, inspection, auditing, certification and training.

The organization is evaluated and accredited (including ISO 17020, ISO 17021) by various national and international bodies for professionalism, ethics, reliability and independence

In 2021, the uST Complex in Sharjah was certified for safety requirements by the independent international organization TUV SW.

The certificate confirms the safety of the technology and applies to the main components of uST Transport & Infrastructure Complex:

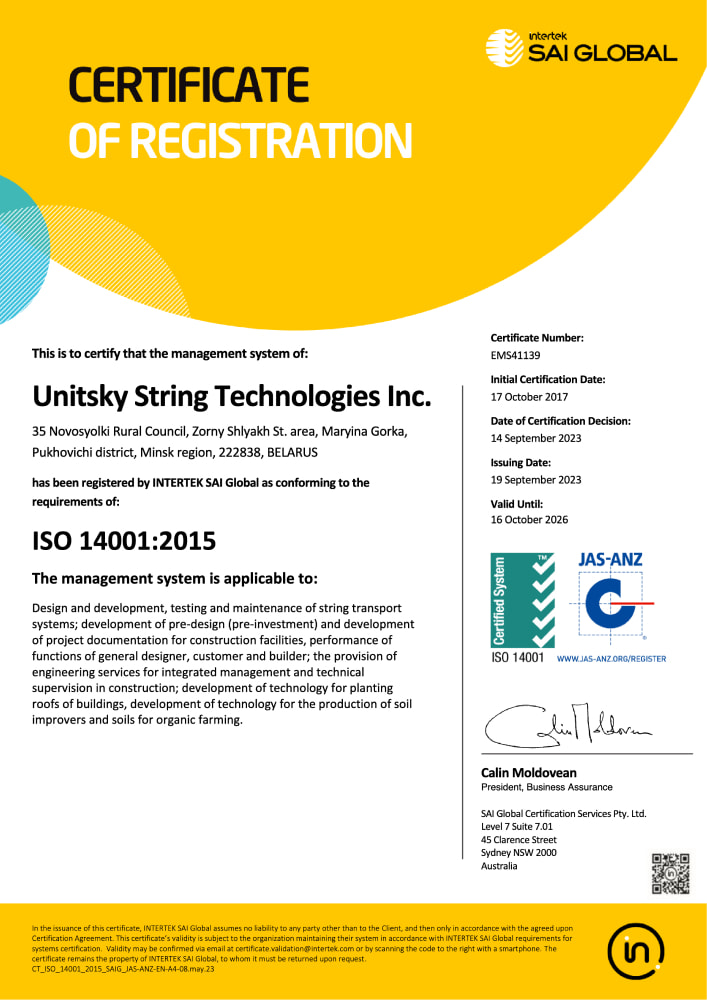

At the moment, the management systems of Unitsky String Technologies Inc. are certified in the international and national conformity assessment systems.

We have obtained certificates of compliance of the quality management system with the requirements of ISO 9001:2015 standards (STB ISO 9001-2015), environmental management system with the requirements of ISO 14001:2015 standards (STB ISO 14001-2017), health and labour safety management system with the requirements of ISO 45001:2018 standards (STB ISO 45001-2020).

The certificates of conformity underlines the ability of Unitsky String Technologies Inc. to provide services that meet the requirements of consumers and legislation for the design, development, testing and maintenance of string transport complexes, as well as development of pre-project (pre-investment) and project documentation for construction projects; perform the functions of general designer, customer and developer; provide engineering services for integrated management and technical supervision in construction. It also confirms our intentions to constantly improve our activities in the field of quality, ecology, health and labour safety.

The certificates of conformity we have received are recognized by the members of the International Accreditation Forum (IAF) which includes more than 90 IAF member countries

Certificates of compliance of the quality management system to the requirements of ISO 9001:2015 standards (STB ISO 9001-2015)

Certificates of compliance of the quality management system to the requirements of ISO 9001:2015 standards (STB ISO 9001-2015)

Certificates of compliance of the environmental management system with the requirements of ISO 14001:2015 (STB ISO 14001-2017)

Certificates of compliance of the environmental management system with the requirements of ISO 14001:2015 (STB ISO 14001-2017)

Audit report of IFRS, 2020

Audit report of IFRS, 2020

Audit report on accounting records, 2020

Audit report on accounting records, 2020

Audit report on accounting records, 2021

Audit report on accounting records, 2021

Audit report of IFRS, 2021

Audit report of IFRS, 2021

Audit report on accounting records, 2022

Audit report on accounting records, 2022

Audit report of IFRS, 2022

Audit report of IFRS, 2022

Audit report on accounting records, 2023

Audit report on accounting records, 2023

Audit report of IFRS, 2023

Audit report of IFRS, 2023

Audit report on accounting records, 2024

Audit report on accounting records, 2024

Audit report of IFRS, 2024

Audit report of IFRS, 2024

Unitsky String Technologies Inc.

Project application220089, Republic of Belarus, Minsk,

st. Zheleznodorozhnaya, 33

Phone: +375 (17) 388 20 20

Fax: +375 (17) 388 06 06

email: info@unitsky.com

222838, Republic of Belarus,

Minsk region, Pukhovichi district,

35 Novosyolki Rural Council,

Zorny Shlyakh St. area,

Maryina Gorka

email: press@unitsky.com

Phone: +375 17 388 20 20, ext. 1308

Thank you for your interest in uST Transport & Infrastructure Solutions. For more information, please include your contact details and answer a few of our questions. Use the online form below.

Please answer all questions, if possible, so that we can provide a more complete answer for you.

Please fill out one form for each project individually.

Try again

The minimum traffic interval is based on the applicable requirements that ensure a necessary level of safety. On the one hand, by the on-line traffic speed, and on the other hand, by the length of the station platform and the time of embarkation and disembarkation of passengers. For single uPods this interval is 25-30 seconds. uPods that are electronically coupled in a train can leave the station one after another with a minimum interval of 2-3 seconds (this is, for example, the interval of cars on the autobahn).

uST Transport & Infrastructure Complex can operate 24/7 on intercity lines (as on railroad) and 20/7 on city lines (as in subway).

Yes, they are GoA4 in the grade of automation (IEC 62290‐1) – unmanned, with central control.

uPods can be located both in special holding stations (“parking lots”) and on the spare lines of stations and in the garages with repair shops (depending on the performance of uST Transport & Infrastructure Complex). During off-peak hours, electric rail cars, if necessary, are removed from the line with the help of appropriate infrastructure components and placed in special holding stations or in service and repair areas.

There are no structural limitation, and the only one is the vertical curvature radius of the track over the support, which determines centrifugal accelerations (no more than 1 m/s2), and thus the comfort for passengers when passing a support. For instance, for a speed of 500 km/h, both horizontal and vertical track curvature radii (including on supports) must be at least 20,000 meters. The combination of structural solutions in uST string rail overpass and rolling stock includes the support saddle, high bending stiffness of the track structure, highly tensioned holding rope, and pneumatic suspension of the wheels, which ensures any required traveling smoothness of uPods, including when passing a support. If necessary, the support section can have reverse curvature of the track (concave curve with bending in the middle of a span), that is the passenger not only will not feel overloads, but on the contrary, his weight will decrease to some extent when passing a support.

Unfortunately, you cannot be 100% sure to guarantee that any component will not fail. However, so far, we have not yet recorded a single malfunction in power supply. The onboard traction electric drive is equipped with a mature cooling system that has independent loops, the products are tested in climatic chamber, the tropical uCar has been successfully operated in the UAE for more than three years already.

We should also highlight that a failure of the traction power supply (e.g., electric substation) will not stop the traffic on the line. Even a failed part of the electric drive system won’t stop the complex, as each system in it is duplicated. Besides, if there are any power supply problems on rails, the onboard emergency battery of uPod will produce enough power for at least 100 km of journey.

Yes, uPod can move at the same speed in reverse direction as a shuttle. The movement direction of the rolling stock is determined by the design of the undercarriage, suspension systems, traction electric drive control systems and the external contours of the body. The main types of uPods will be operated without any reference to directionality, as this solution is universal, which also allows reducing the operating costs. At the same time, of course, there are also solutions with unidirectional movement, which is a priority in a number of projects, especially with large passenger and cargo flows.

uST Transport & Infrastructure Complex can be designed both for operation in freezing climate (down to -60 °C) and for in tropical conditions (+50 °C with extension of operating temperature up to +55 °C).

Today, string transport is operated both in temperate climate (the bottom temperature limit is -40 °C in Belarus) and in the tropics (up to +55 °C in the UAE).

As for rainfall, uPods are undergo sprinkling tests with rainfall intensity of at least 2-3 mm per minute, which corresponds to a heavy tropical downpour.

Humidity is up to 100% inclusive under appropriate conditions of the climatic region.

Wind stability for the complex to operate in a standard version is 90 km/h (25 m/s). Anything higher – up to 250 km/h (70 m/s) – is possible in a special version based on customer requirements.

Probably. Our uPods are prepared and already operated in harsh conditions, including sandstorms, in Sharjah (UAE). The possibility of operation is ensured by a number of structural solutions in the infrastructure components of the string rail overpass, rolling stock, including a mature filtration system and installation of various cleaning systems. Such systems include, for example, a device to clean the rolling surface of the rail from stuck sand or the traction module blowing system.

Prestressed strings are elements in which tensile stress state is created in various ways, so in its design essence it is a prestressed bearing reinforcement. The company mainly uses reinforcing ropes.

The vertical load is distributed to supporting towers, installed at intervals of up to 2 km. The string rail track structure looks light and delicate: it does not block the sky and preserves natural landscapes along the route of laying tracks.

The strength of a string rail in such structures is ensured by choosing materials with certain strength characteristics, selecting the necessary rigidity and creating a tensile prestress state, which holds the superstructure.

The most material-intensive and expensive overpass of the listed ones is rigid, while the lightest and most inexpensive is flexible.

The energy consumption of uPods is 2–3 times lower than in traditional modes of transport using steel wheels or a magnetic cushion. If we compare this figure with road transport, including a traditional electric car on pneumatic tires, then it is 5–7 times lower.

Conventional electric vehicles use pneumatic tires, which, when worn together with asphalt, emit soot, benzopyrene, phenols and other carcinogens (more than 100 of them) into the air, while some carcinogens are contained here in greater quantities than in automobile exhaust. At UST Inc. this problem is solved due to the use of steel wheels of a special design – more efficient, for example, in comparison with railway wheelsets.

A uPod is more environmentally friendly than a traditional electric vehicle, which consumes several times more electricity and takes up space on a city road, which leads to traffic jams in which toxic substances are released. uST vehicles move above the ground and eliminate the problem of traffic jams.

Noise and vibration from uST transport is significantly lower than from a railway, tram or monorail. It has already been studied that, for example, in the Moscow metro, the presence of a passenger will be safe only for the first three seconds. Further, negative factors begin to affect the human body – an isolated and compressed space, powerful electromagnetic radiation, as well as the strongest noise and vibration. While uPods do not have even a small share of such a negative impact on a person.

uPods, including those assembled into trains, can have different capacities – from 2 to 250 passengers. Their design is separate modules, combined into a composition through a rigid or electronic coupling. Such a train is capable of transporting up to 50 thousand people per hour, that is, at the level of the metro and the railway. The number of sections and their capacity depends on the passenger flow. The uPod is driven by a traction electric drive. Speed and route control are provided by automated control systems.

uST transport can carry different types of cargo: bulk, liquid, piece, special, as well as sea containers with a nominal length of 20 and 40 feet. Their loading and unloading occurs automatically. Speed and route control are provided by automated control systems. Cargo transport is capable of carrying up to 100 million tons of cargo per year.

The string rail overpass is located above the ground, so collisions with ground vehicles (buses, cars or agricultural machinery), pedestrians or animals are impossible. The prestressed track structure maintains the operability of the uST complexes even if one or more supporting towers are damaged in the event of natural disasters or other force majeure circumstances. In such a situation, the string rails will sag more, but they will not break and their performance will not be impaired. The collapse of the track structure is also excluded in case of damage and rupture of individual strings (up to 50% of their total number), for example, as a result of a terrorist act.

Features of the uST transport and infrastructure complex elements make it possible to use it in regions with difficult climatic conditions. Pre-tensioning of rails solves the problem of temperature deformations and allows transport to operate at abnormally high and low temperatures.

The change in the characteristics of the rails under the influence of temperature is included in the project so that it does not affect the performance of the uST complexes, as well as the speed limits and the comfort of transportation. When the temperature changes, the length of the string rail does not change – the structure is prestressed and only the tensile stresses in the rail change, which ultimately makes it possible to abandon the expansion joints that affect the performance properties. The safety margin of strings is such that they will be broken only if they are cooled to the temperature of liquid nitrogen – about −200 °C.

The uST transport overpass in terrestrial conditions is designed for a temperature difference of 120 °C: from −60 °C to +60 °C. It is resistant to snow drifts up to 10 m high, icing and sandstorms, floods up to 10 m high and tsunamis, heavy rains and fogs, storm winds up to 250 km/h, earthquakes of 9 points on the Richter scale and other extreme impacts, including vandalism and terrorist acts, if such impacts are considered probable in the project, even with a probability of once in 100 years.

Control system for uST transport and infrastructure complexes is automated. Using the technical vision of the uPod onboard control system, they continuously read information from the track structure, monitor the fulfillment of the route task, and also instantly respond to obstacles and threats. Their task is to ensure comfortable and safe transportation of passengers, as well as reliable and trouble-free transportation of goods.

The systems receive, process and analyze information thanks to sensors and fully control the route and speed of movement, independently make decisions to reduce speed or stop if obstacles are detected on the route. It provides for real-time data exchange with elements of the transport and infrastructure complex, as well as obtaining up-to-date information from other uPods.

Automated systems provide control over the state of safety in the uPod cabin and coordinate the processes of embarkation and disembarkation of passengers. The systems are able to recognize the actions of passengers that may pose a safety risk and take measures to prevent dangerous situations. For example, acts of terrorism and vandalism.

The number of personnel required to maintain the operation of the complex is determined individually for each project, but it is much less than, for example, on a traditional railway or on high-speed roads with a magnetic cushion. uST facilities need mechanical engineers, telemetry and communications engineers, locksmiths, mechanics, security guards, and other traditional professionals.

The costs for the construction of a specific uST transport and infrastructure complex depend on the planned volume of traffic, estimated speeds, the nature of the terrain and climatic conditions, the type of logistics tasks and, accordingly, the design option. At the same time, factors such as the total length of the route are important (the longer it is, the cheaper the subsequent kilometers), the terrain (plain, sea shelf, foothills, mountains), the height of the supports (the higher the path is placed, the more expensive it is), the strength of the underlying soil (sand, rocky soil, swamp), the presence of obstacles (rivers, lakes, gorges), etc.

Compared to existing overpass transport solutions (monorail, cable car, light rail transport, high-speed tram, metro, etc.), the cost of construction and operation of uST complexes is several times lower, primarily due to a decrease in the material consumption of all elements of the complex, as well as due to reducing the construction complexity. In the production of rolling stock, i.e. rail electric vehicles on steel wheels, a small consumption of structural materials is also required. The absence of massive drives, powerful frames, heavy undercarriages and wheelsets significantly reduces the cost of rolling stock production.

Resistance to external influences and durability of the string rail overpass provide low operating costs. Regular replacement of the complex elements is not required, while service intervals are significantly increased in time and mileage. The service life of the overpass before overhaul is from 50 years, while for the rolling stock this figure is from 25 years.

Maintenance of the transport complex requires work on pre-trip inspection of rolling stock and interval inspection of track structures by automatic devices as well as periodic testing of the control system with related subsystems.

It is easier to integrate a string rail overpass into an already formed urban environment than to build a new metro, railway or highway. The light string rail track will harmoniously fit into the architecture of any settlement, cross city streets, roads and rivers, and, if necessary, pass over parks and low-rise buildings. Existing communication networks can be integrated into the transport overpass, no radical re-planning of the city infrastructure is required. Passenger stations are combined with anchoring structures. Stations can be used as commercial real estate, placing cafes, shopping and entertainment centers, hotels, pharmacies and other facilities in them. Stations can also be used as additional advertising space. Due to this, the payback period of uST complexes is reduced.

The capacity required to power uST systems varies by project. Depending on the logistics, the number of stations, length of the complex, passenger traffic, traffic speeds, and power consumption will be determined. In any case, uPod fleet, with similar transport work, will require approximately 5 times less primary energy (starting from fuel combustion in a power plant) than, for example, a Tesla electric vehicle fleet.

Therefore, uST is the “greenest” transport of all possible, including in comparison with traditional electric vehicles and magnetic levitation trains.

Transport and infrastructure complexes of Unitsky String Technologies are characterized by almost zero environmental impact and low noise level. Electric rail vehicles on steel wheels run on the most environmentally friendly form of energy – electricity. Transport should peacefully coexist with nature, and not be at enmity with it, complement it, but not replace it – this is the approach the company adheres to when developing its solutions.

Ecologically clean string rail roads are dotted on the ground. This advantage, with the widespread use of transport and infrastructure complexes, can save vast territories for land users, which would otherwise be occupied by traditional transport communications. For example, under roads and railways, soils which area is five times bigger than the territory of Great Britain have already been destroyed on the planet. Vegetation will remain in the areas saved by uST, annually replenishing the atmosphere with billions of tons of life-giving oxygen. The severity of environmental pollution problems will then decrease to a safe level.

UST Inc. is an engineering company primarily that has the status of a scientific organization in Belarus. Our employees are involved in the development, production, service, testing and marketing of our uST transport and infrastructure complexes. The company is developing due to its investors who believe in technology and its scaling, launching global projects in different countries and continents. They do not invest directly, but through special crowdfunding platforms.

The competitors of UST Inc. are transport systems of the “second level” above ground, such as cable cars, light rail transport, elevated and underground metro, monorail, trains on a magnetic or air cushion. The main advantage of uST is the significantly lower cost of the transport and infrastructure complex with lower operating and transportation costs.

Any transport is created for the sole purpose of providing a transport service, where the following criteria are decisive: the cost of service, the safety of service, the availability of the service (in time and space), its comfort, energy efficiency, resource intensity, environmental friendliness, etc. As for the complex of these parameters, so and for some of them, uST has no equal among the listed and promising competitors. Behind this are not emotions, but the laws of physics.

The uPod must be removed from the route to perform additional checks and determine the causes of the breakdown. However, the probability of such a risk is extremely low. The main systems that ensure a safe transportation process have multi-circuit redundancy. In addition, the rolling stock is equipped with systems that make it possible for its automated evacuation by neighboring uPods located on the line. The uST complex also provides access for special equipment (module with tow device) and maintenance personnel to perform forced evacuation.

Emissions of harmful substances in electrified uST complexes are practically absent, amounting to only 0.1 g/pass-km. This is especially noticeable against the background of traditional modes of transport. On high-speed railways this figure is approximately 0.6 g/passenger-km. Vehicle emissions of harmful substances are on average more than 10 g/pass—km. Aviation pollutes the atmosphere the most. If we take modern aircraft, the total emission of harmful substances reaches 300-400 g/pass-km.

uST transport is virtually silent even at high speeds. The exceptionally quiet and smooth rolling of the steel wheel is ensured by several factors:

The friction forces in the steel wheel-steel rail head pair will ensure a steady rise with a slope of up to 15% if all wheels of the uPod are driven. At climb angles of 20-30%, each uPod must be equipped with an additional group of rollers that create the required coupling force for a given section of track.

Each electric rail vehicle can be assembled into trains by means of a rigid (physical) or electronic (control system-based) coupling.

Standard power is supplied from the contact network on electrified sections of the track and from an energy storage device on non-electrified ones. In the event of a drive failure in an unelectrified section, the transport will be slowed down. Information about the malfunction will be sent to the central control system. If the uPod is unable to continue driving on its own, it will be towed to the nearest station for disembarking passengers, and then to a garage combined with a repair shop.

The uST solution allows you to transport:

The terrain is not important for the uST complex, so the route will take the shortest path — in a straight line. If necessary, the track structure can have curvature in both the vertical and horizontal planes.

Overloads on curves should not be felt by passengers, therefore, the radii of curvature of the route for a speed of 300 km/h should be at least 10 km, for 400 km/h — at least 15 km, for 500 km/h — 20 km. For smaller turning radii of horizontal curves, bends performing is provided. Curves can have a radius of, for example, 1000 m, but then on these sections of the route the speed should be no more than 100-150 km/h.

The minimum radius of the curves is 10 m (at stations, terminals, or garages combined with a repair shop, where the speed of electric rail vehicles is close to zero). At the same time, on curved sections of the route with a radius of less than 100 m, the rail will be made without strings (according to the type of railway rails) and supported by beam or truss superstructures of both conventional design and string type.

The anchor structure can be combined with turns at the station or be common to two track structures at the turn.

Electric rail vehicles provide for an independent emergency evacuation in case of force majeure, when there is nowhere to wait for help: an earthquake, a terrorist attack, etc.

The passenger module is equipped with a rope-lowering rescue device of the tow truck type (for small-capacity uPods carrying up to 25 people), so that any passenger can descend to the ground.

Each large-capacity uPod (carrying more than 40 people) is equipped with a rescue sleeve and a folding ladder, which will also ensure the rapid evacuation of people from the aboveground “second level”, if necessary.

In addition, the emergency electric drive and control system in such cases will ensure that uST transport stops not in a random place, but precisely where it is possible for passengers to safely descend to the ground.

It is impossible to name a fixed figure, since the cost of building 1 km of the uST track is influenced by the following factors:

At the same time, the cost of building 1 km of the uST complex transport overpass, other things being equal (i.e. climatic and infrastructural conditions), will be: from 50% of the cost of building 1 km of cable car, from 10% of the cost of building 1 km of light rail overpass, from 4% of the cost of building 1 km of subway.

If necessary, the station can be integrated into an existing building, taking into account the assessment of economic and technical feasibility.

There will be no longitudinal temperature deformations at all — neither in the body and the rail head, nor in the string. After all, their length remains unchanged in summer and winter. The rail and the string a priori do not have temperature deformation seams along their length, just as telephone wires or power line wires do not have them, which, like the strings in the rail, are sagging between supports and stretch without joints for many kilometers.

However, it should be borne in mind that a change in temperature in the structure can lead to changes in its stress-strain state. Therefore, the uST track structure is designed so that only tensile forces are present in the rail and string at any calculated temperature changes. In this exact case the structure will never lose stability, which would’ve happened if compression forces appeared in these elements.