Cheaper and more reliable than conventional transport: features of the uST complex operation in winter

Preparation for winter is an important part of urban public transport service. It takes a lot of time and money. UST Inc. has developed a passenger transport solution that is more efficient than the existing ones. Let’s compare the winterization preparations of conventional transport infrastructure and the uST complex.

Bus

The inner nodes and assemblies of the bus are under heavy pressure in winter due to a number of factors: frost, ice and snow on the road.

At low temperature, there is a sharp increase in fuel consumption, wear of engine parts and transmission, as before the operation is started long-term heating is required.

Cold fuel doesn’t burn completely and its consumption increases, which seriously reduces the engine life. The cylinder block gaskets get burned, fuel filters and nozzles become clogged, and fuel pumps fail.

Chemical reagents sprinkled on the roads for melting ice and snow in the city cause no less problems. Most often it’s sodium chloride. When it gets wet, it creates heat that melts snow, but at the same time produces a weak hydrochloric acid solution. When it hits open areas of metal, it quickly corrodes them. Places near sills and wheel frames are affected the most.

As a result, through holes which have to be patched form in the bus floor just in a couple of winters.

Tram

The tram contact network requires seasonal adjustment. Before the cold, electricians weaken its tension, otherwise the wire may break when the metal is contracted in cold weather.

It also requires inspection and additional impregnation of electrical machines, engines, as well as replacement of technical liquids and oil. Brake actuators and electromagnets shall be carefully inspected as well.

The tramway track itself requires special attention. Before the season starts, it is necessary to repair the butt gaps, check the electrical connections, lubricate and tighten the bolts, as well as clean the drains.

In winter, the snow that got inside the switch can lead to an unpleasant outcome. Therefore, in case of heavy snowfall, the employees of the tram depot turn off automated arrows. Drivers have to get out of the tram, clear the snow and manually move the arrow. Of course, it is unsafe and greatly slows down the movement.

Trolleybus

Pre-winter preparation of the trolleybus is similar to that held for the tram and bus. Vehicle windows and doors are made insulated, often with the help of special rubber that fits snugly and is airtight. Tires are changed to the winter type ones, new oil is poured, additional heaters are installed.

The braking system also needs to be thoroughly checked. The ingress of moisture and its subsequent freezing cause an emergency stop. As a result, the trolleybus can block the line for several hours.

Also, in winter constant maintenance is required by the contact network, without which the movement of trolleybuses is impossible.

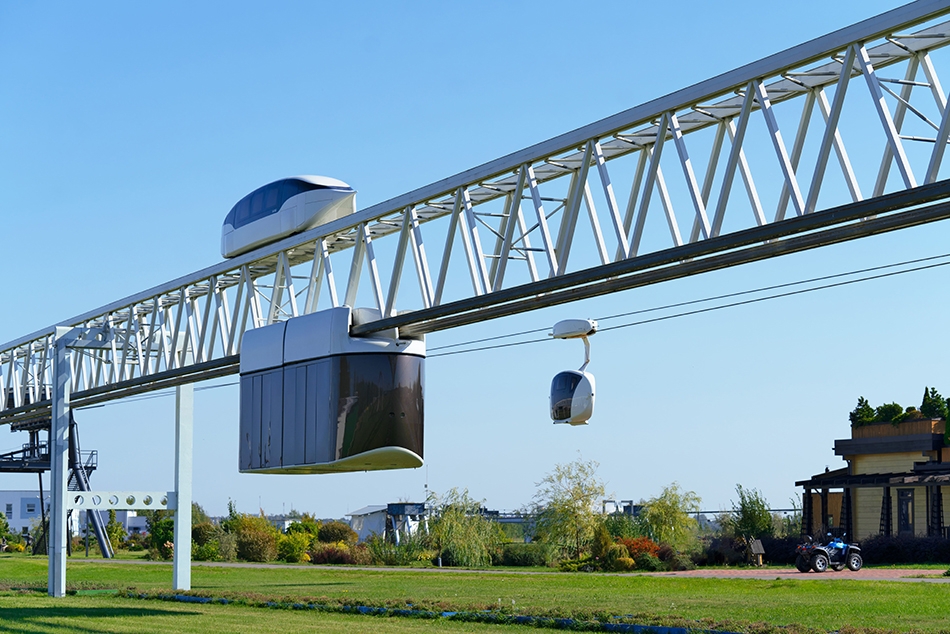

uST complex

The preparation for winter operation of the rolling stock of the uST complex – uPods –– does not require a lot of expenses and includes check-up of energy storage, cooling, air conditioning and other systems.

Of special arrangements one can mention the use of liquid heaters for effective charging of storage devices.

Unlike buses and trams, uPods move above ground. Therefore, they do not suffer from the effects of corrosive anti-ice mixtures, capable of destroying the steel hull in a couple of seasons. This is one of the reasons why the service life of rolling stock of the uST complex is 25 years.

The uST complex is not afraid of track icing as the track structure cleans itself after every uPod passage. Therefore, snow and ice cannot accumulate on the road and pose danger to traffic, as in the case with ground urban transport.

Significant savings

To sum it all up, the uST complex has many advantages over ground urban transport. The operation of uPods does not require large quantities of petrol, oil and lubricants as well as expensive spare parts, as buses do. The contact network doesn’t require constant attention as in the case of trams which often suffer in winter from accidents on it. You can also do without cleaning the roadbed, which is necessary for all ground urban transport. And there’s no need for a lot of support staff.

More news

Interviews

27 Junе 2023

The Interview with General Designer of UST Inc.: “The Essential Part of Transportation on the Planet Will Be Transferred to the “Second Level” by 2051”

Anatoli Unitsky shares his forecast in a new interview published by WORLD 2051 media project.

News

29 April 2024

UST Inc. Is Working on the Development of Standards for uPods in Belarus

The State Committee for Standardization of the Republic of Belarus has accepted an applica-tion for the creation of a regulatory framework for rail electric vehicles.

News

21 August 2024

UST Inc. named the most demanded specialties for the development of uST complexes

One of the company’s strategic goals is to find and develop talented professionals who possess a deep understanding of the UST technology’s nuances.