A New Standard of Strength: ETFE Films in uST Transport Complexes

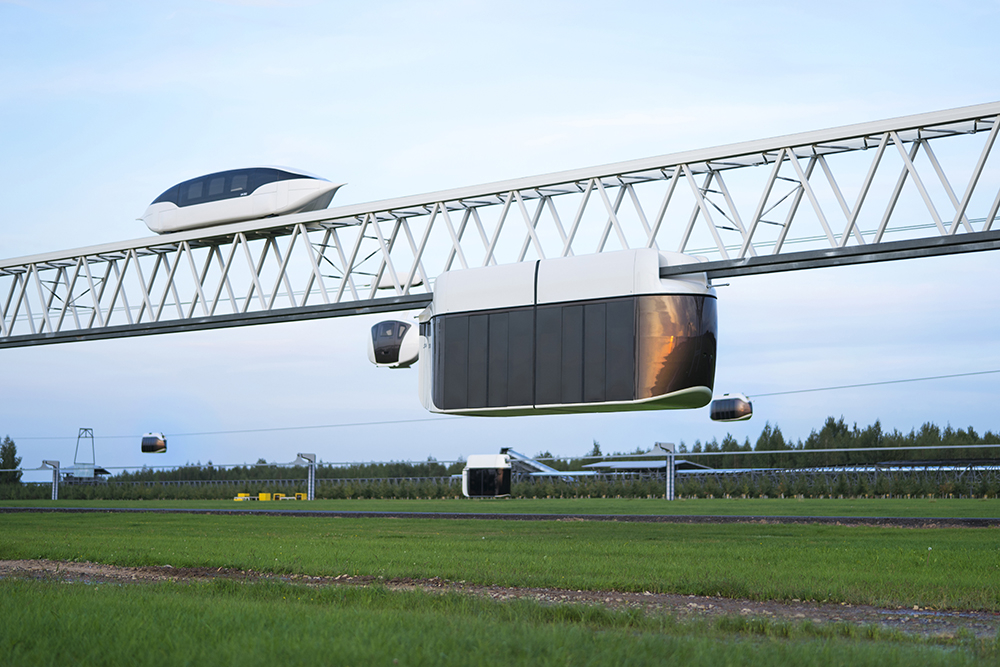

Modern transportation infrastructure is increasingly designed using advanced materials that are lightweight, strong, transparent, and resistant to external influences. One such material is ETFE film – a fluoropolymer with a unique combination of mechanical strength, chemical inertness, and minimal weight.

Modern transportation infrastructure is increasingly designed using advanced materials that are lightweight, strong, transparent, and resistant to external influences. One such material is ETFE film – a fluoropolymer with a unique combination of mechanical strength, chemical inertness, and minimal weight.

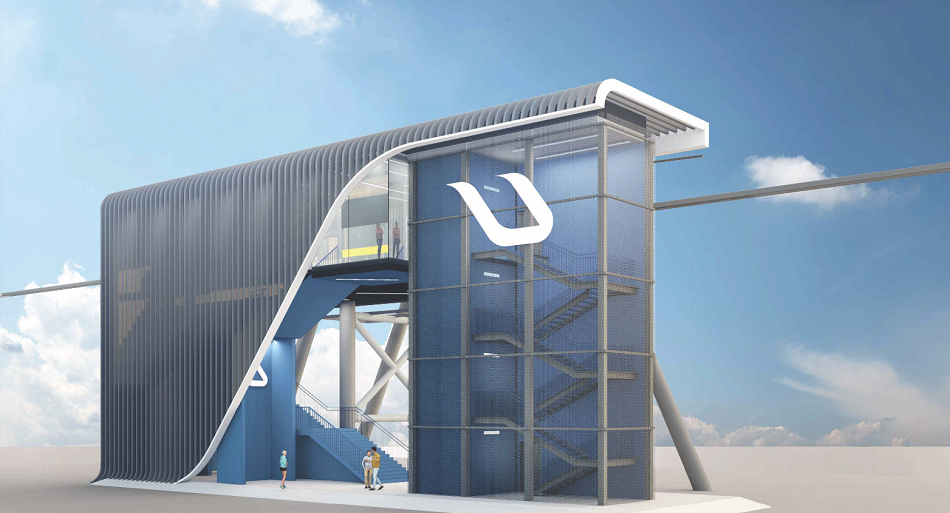

Today, ETFE is widely used in the architecture of airports, stadiums, and public spaces. Engineers at Unitsky String Technologies Inc. have adapted this material for use in uST transport-infrastructure complexes, developing specialized mounting systems that transform the thin membrane into a fully functional element of the cladding shell for stations and terminals.

ETFE – A Material for Next-Generation Infrastructure

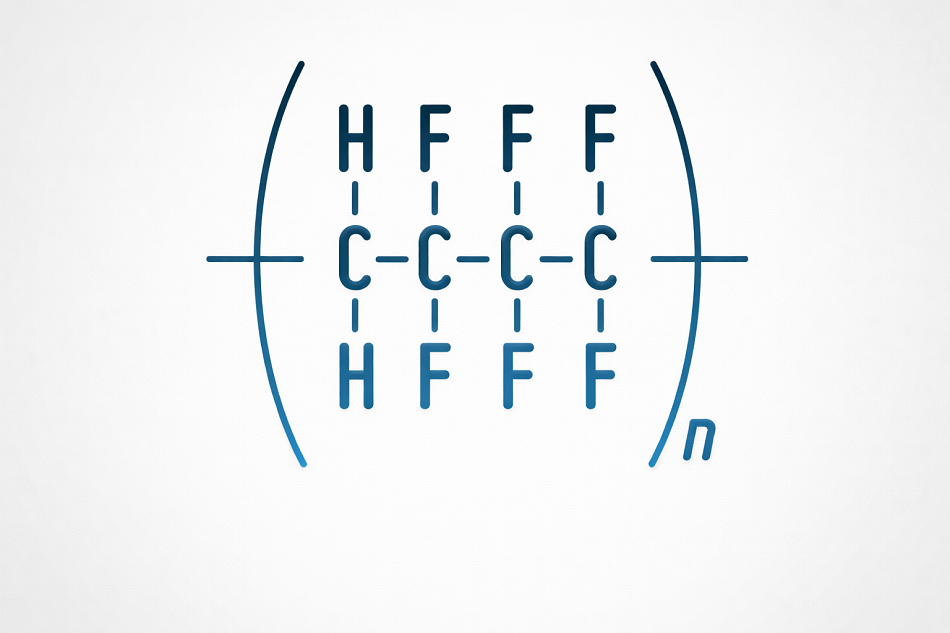

ETFE (ethylene tetrafluoroethylene) is a transparent fluoropolymer that is stronger than glass but is nearly 100 times lighter. The material is resistant to ultraviolet light, does not yellow over time, and maintains its elasticity and mechanical properties within a temperature range of −80 to +150 °C.

For uST transport complexes, ETFE has become a promising solution for creating awnings, facade shells, pavilions, and passenger stations. These structures boast high light transmission, low weight, and durability.

However, the low rigidity of the membrane material precludes the use of traditional mounting methods typically employed for glass and polycarbonate. With rigid fixation, the film can break, while insufficient tension may cause deformation under wind loads.

Engineering Challenge: How to Secure the Unbondable

One of the key characteristics of ETFE is its ultra-low surface energy – approximately 18–20 mN/m. In comparison, plastics have a surface energy of 30-50 mN/m, glass ranges from 300-400 mN/m, and steel can go up to 2000 mN/m. This makes adhesive bonds unfeasible, as adhesives do not form adhesion or wet the surface of the material.

Thermal welding is also not applicable; ETFE does not melt like traditional polymers but decomposes at high temperatures while maintaining low adhesive capability. Additionally, the coefficient of friction for this material is only 0.04–0.1 – one of the lowest among structural materials.

Therefore, in all major architectural projects worldwide, ETFE coatings are mounted exclusively using mechanical methods – employing tension frames, clamping profiles, cable systems, and wedge systems. A similar approach has been implemented in the uST complexes.

Carefully Yet Reliably

The main engineering challenge when working with ETFE is to ensure an even distribution of loads across the membrane surface. The film functions as a tensioned shell, and any localized force may lead to stress concentrations, the formation of wrinkles, and loss of tightness.

Engineers at UST Inc. have explored several types of fastening solutions, including:

- Linear clamps – profile systems with elastic seals that secure the film without puncturing it;

- Point compensating nodes – anchoring elements with fluoropolymer inserts to compensate for micro-deformations;

- Cable and wedge systems – a combination of tensioned cables and locks that create uniform tension around the perimeter.

Depending on architectural and climatic conditions, both standalone solutions and hybrid fastening schemes are utilized.

Testing and Reliability Confirmation

To test the durability of the structure, specialists from Unitsky String Technologies Inc. created a prototype of a uST passenger station, exposing the ETFE shells to wind, snow, and temperature loads.

The hybrid scheme yielded the best results: linear clamps around the perimeter of the span and point compensators in the central zone. This system withstood wind gusts of up to 35 m/s and temperature fluctuations from −40 to +60 °C without micro-damage or loss of tightness.

Additional resource tests confirmed the retention of operational properties after 50,000 deformation cycles simulating daily temperature variations over 10 years of use.

Architecture of New Transport Infrastructure

The use of ETFE films in combination with specialized fastening systems opens up new possibilities for designing uST stations and terminals. Transparent shells enable the creation of energy-efficient spaces with natural lighting, the integration of solar panels, lighting systems, and self-cleaning surfaces.

The low weight of enclosing structures reduces the load on supports and foundations, decreases material consumption, and enhances the economic efficiency of the infrastructure. This concept demonstrates how careful engineering of even an element like a fastening node can influence the development of an entire technological platform.

In the future, such shells may become the standard for “second-level” stations and terminals, combining durability, energy efficiency, and visual lightness. The engineering solutions developed by specialists at UST Inc. confirm that even the most delicate structures can be reliable when supported by precise calculations and a systematic approach.

More news

News

25 October 2022

Unitsky String Technologies Inc. Unveils New Website

User-friendly, informative and intuitive – the new website of UST Inc. is already available for users. The portal provides information about uST Transport & Infrastructure Complexes, the advantages of the technology and the company's activities.

News

24 April 2025

Three Years Ago, UST Inc. Gained Scientific Organization Status

In April 2022, Unitsky String Technologies Inc. became one of eight private organizations in Belarus to undergo accreditation by the National Academy of Sciences and the State Committee on Science and Technology, receiving the corresponding certificate.

Opinion

4 February 2022

Unitsky String Technologies Inc. Found Itself in the Spotlight of Many Media in January

Journalists regularly choose string transport as a subject for their article or story. The past month has once again confirmed this. We bring to your attention an overview of the most interesting publications about Unitsky String Technologies Inc.