Advantages

Engineering developments and know-how of Unitsky String Technologies Inc., which are the basis of uST Transport & Infrastructure Complexes, provide a number of characteristics that allow not only to compete with other transport systems, but also to considerably surpass them

uST transport and infrastructure complexes can be easily adapted to perform any logistics tasks in the field of urban and intercity passenger and freight traffic at speeds of up to 150 km/h. The complexes are distinguished by high efficiency, safety, reliability and durability. In addition, they are more profitable in terms of construction and operating costs compared to other types of overpass transport (monorail, ground and underground metro, high-speed tram, cable car)

Key figures

- Average capital expenses (CAPEX)*

- Travel speed in urban modes of transport*

- Comparison of carrying capacity of different modes of transport complexes

CAPEX $ mln/km

Monorail

Light rail transport

Ropeway

Metro

High-speed tram

High-speed railway transport

uST

* depends on the country of implementation and technical and economic indicators of the project (from open sources of information in average prices as of 01.07.2022)

Speed Average/Maximum, km/h

Ropeway

High-speed tram

Monorail

Light rail transport

Metro

uST

* based on public sources

Passengers per hour

Ropeway

High-speed tram

Monorail

Light rail transport

Metro

uST

* based on public sources

Сomparison with the rivals

Passenger transport

uST

Ropeway

rolling stock – 25 years

uST

Metro

uST

Light rail transport

uST

Monorail

rolling stock – 25 years

rolling stock – 10-15 лет

Cargo transport

uST

Narrow-gauge railway

NGR

10 km/h – loaded stock

rolling stock – 25 years

uST

Railway transport

uST

Ropeway

rolling stock – 25 years

Availability

- Low material consumption

- Minimum land allotment

- Low operating costs

- Automation of the transportation process

Compared to existing overpass transport solutions (monorail, cable car, light rail transport, and express tramway), the cost of building and operating uST transport and infrastructure complexes is much lower. The product of Unitsky String Technologies Inc. is highly commercially available due to a combination of unique characteristics

Features of the prestressed string rail structure make it possible to reduce the material consumption and cost of transport overpasses by an order of magnitude. During the construction of uST Transport Complexes, there is no need for the construction of earth embankments, excavations, bridges, overpasses, multi-level interchanges and culverts

The track structure requires minimal land allocation for construction and a small amount of earthworks. The “second level” factor saves space and does not interfere with the usual use of territories: agricultural areas, recreational and pedestrian zones, etc.

Resistance to external influences and durability of the string rail overpass provide low operating costs. Regular replacement of the complex elements is not required, while the service intervals are significantly increased in time and mileage. The service life of the overpass before overhaul starts from 50 years, that of the rolling stock is 25 years.

The design of the string rail overpass makes it possible to lay a route along a shorter trajectory. Due to the long spans between the supports, the route can be laid over a water barrier or other difficult terrain without the use of additional structures. This not only shortens the distance to the destination, but also saves money (no need to build additional kilometers of the route), and also reduces operating costs

Production of rolling stock – steel-wheeled rail electric cars – requires a low consumption of structural materials. The absence of massive drives, hefty frames, heavy undercarriages and wheel pairs can significantly reduce production costs

The high energy efficiency of uST transport, which is ensured by the high aerodynamic design of uPods, their movement on steel rails and the low value of the resistance of movement due to the absence of losses on the hysteresis of the elastic elements of the wheel propellers, makes it possible to achieve minimal operating costs. In addition, when using a flexible type of track structure, it is possible to use gravitational forces during the acceleration of a uPod on the descent between the adjacent supports. On long stretches, uPods can accelerate up to 150 km/h without using electricity, which also helps to reduce energy consumption.

uST Transport & Infrastructure Complexes are ready to ensure the transportation of the maximum number of passengers (up to 50,000 people per hour) at minimal operating cost due to high speed and a minimum traffic interval from 20 seconds. This feature, along with the automation of the transportation process, energy efficiency and the need for only a small staff of maintenance personnel, reduces the period of self-repayment of the complex

Safety

- Location of the track structure high above ground rules out accidents

- Movement of the rolling stock on a firmly secured track

- Anti-derailment system on each uPod’s wheel

- Automated control system

- Data exchange between uPods on the line

uST transport and infrastructure complexes are distinguished by a high level of security. A multi-level system has been created, the elements of which exclude any incidents and accidents during the operation of the complex

The string rail overpass is located above the ground, so collisions with other vehicles (buses, cars or agricultural machinery), pedestrians or animals are simply impossible. The prestressed track structure allows the uST Complexes to remain operational even if one or more supporting towers are damaged in the event of natural disasters or other force majeure circumstances. In such a situation, the rails will sag to a greater extent, but they will not break. The track structure will also not collapse if individual strings (up to 50% of the total) get damaged or broken, e.g. in a terrorist attack.

Rail electric cars move along a firmly secured track and exchange data between one another and the control room in real time. This eliminates the risk of emergency situations when the cars are moving or stopping on the line, or when losing control. uPods are equipped with an anti-derailment system that prevents them from derailing, overturning and/or falling. The automated control system makes the string transport resistant even to the most difficult weather conditions: snowfalls, heavy rains, dust and sand storms, etc.

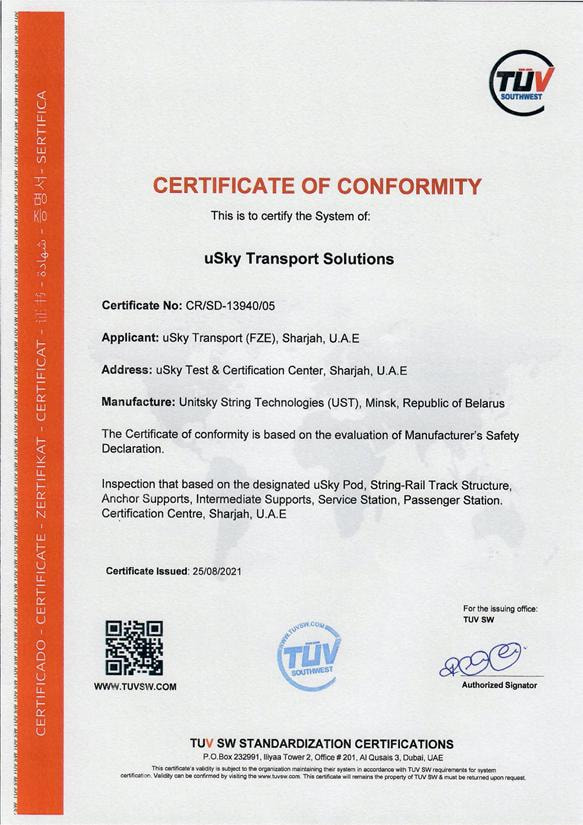

Unitsky String Technologies Inc. develops and manufactures transport and infrastructure complexes in accordance with strict international standards

The safety of uST Transport & Infrastructure Complexes has been confirmed in the UAE by the international independent organization TUV SW. Certification covers the main structural elements of the complex: a string rail transport overpass, electric vehicles on steel wheels with an automated control system, anchor and supporting towers, passenger and service stations, control room and utilities

uST Transport & Infrastructure Solutions provide safety when used during epidemics and pandemics. For example, the accumulation of a large number of people in a conventional train car, bus or trolleybus contributes to the spread of viral diseases. At the same time, uPod models of different capacity allow transporting both small groups of people and tens and even hundreds of people. If necessary, only small vehicles can be used on the line. Adaptation of transport operation to passenger traffic performed by the automated control system will prevent crowding at stations if necessary

Adaptability

- Inclusion in areas with difficult terrain and weak and permafrost soils, as well as quake-prone regions and flood zones

- Integration of external communications – product, electrical, and information networks – over existing infrastructure

- Construction over existing communication, residential, and industrial infrastructure

- Adaptation of passenger capacity and traffic intervals of rail electric vehicles to peaks and declines of passenger traffic

uST Transport & Infrastructure Complexes are characterized by a high level of adaptability. They can be built in areas with complex terrain and extreme natural and climatic conditions. The possibility of laying transport and infrastructure communications over existing roads and railways, power lines, residential and industrial development areas also makes the uST Solutions flexible in use. Thanks to this, the problems of congestion and traffic jams on roads in cities can be solved, the load on existing transport communications is reduced

The track structure is designed in such a way so that it can be used both for the transportation of passengers and for the transportion of goods. It is easier to integrate a string rail overpass into an already formed urban environment than to build a subway, railway or highway there. A light string rail track will harmoniously fit into the architecture of any settlement. Existing communication networks can be integrated into the transport overpass, no radical re-planning of the city infrastructure is required. Passenger terminals are combined with anchoring structures. Stations can be used as commercial real estate, accommodating cafes, shopping and entertainment centers, hotels, pharmacies and other facilities. They can also be used as additional advertising space. Due to this, the payback period of uST Complexes is reduced

uST Transport & Infrastructure Complexes are built and operate on the principle of modularity. If necessary, the transport is easily coupled into trains with a large number of vehicles. Their number in the coupling, as well as models of uPods are selected depending on the logistics tasks for a particular project.

Automated control system adapts traffic intervals of uPods to the number of passengers at the station. Due to the speed of up to 150 km/h and the minimum traffic interval (20-30 seconds), rolling stock with a capacity of 6 to 250 people will be able to provide efficient and safe transportation of passengers – up to 50,000 people per hour.

Features of the elements of the transport and infrastructure complex make it possible to use it in regions with difficult climatic conditions. Pre-tensioning of rails solves the problem of temperature deformations and allows transport to operate at abnormally high and low temperatures. The prestressing of the track structure in the complexes is calculated taking into account the temperature regimes typical for the areas of operation. Changes in the characteristics of rails during thermal expansion and contraction are included in the design so that this does not affect the performance of uST Complexes, as well as speed limits and the comfort of transportation

Environmental friendliness

- Preservation of natural ecosystems and biogeocenoses under the road

- Preservation of animal migration routes and soil hydrology

- Electricity use

- No exhausts, tire and asphalt wear products

- Low noise

Transport and infrastructure complexes of Unitsky String Technologies Inc. have virtually zero environmental impact and low noise levels. Transport should peacefully coexist with nature, and not be at loggerheads with it, complement it, not replace it – this is the approach the company adheres to when developing its solutions

The maximum environmental friendliness of string transport is achieved due to the low material consumption of the structural elements of the string rail overpass and rolling stock, minimal land acquisition, operation on electricity and its low consumption, as well as due to the movement of vehicles high above the ground. These unique features make it possible to use uST Transport & Infrastructure Complexes even in regions with the most stringent environmental requirements.

Steel-wheeled rail electric cars run on the most environmentally friendly type of energy – electricity. Moreover, high energy efficiency of uST transport is achieved due to the movement of steel wheels on steel rails with an efficiency of 99.8% and high aerodynamics of the rolling stock. This is the most important moment. After all, large consumption of electricity also harms nature, since this resource is often obtained at coal-fired power plants that emit flue gases with harmful cancerogenic substances into the air. By the way, the energy consumption of uPods is 2-3 times lower than in traditional modes of transport using steel wheels or a magnetic cushion. And if we compare this figure with road transport, including conventional pneumatuc-tyred electric cars, then it is even 5-7 times lower

uPods are more environmentally friendly than conventional electric vehicles, which consume way more electricity and take up space on the city road, resulting in congestion that releases large amounts of toxic substances. String transport moves high above the ground and rules out the problem of traffic jams.

Conventional electric vehicles use pneumatic tires that, when rubbed off, together with asphalt, release soot, benzapyrene, phenols, and other carcinogenic substances into the air (over 100 of them), and some of them are contained here in greater quantities than in car exhaust. In turn, tire production and disposal of spent tires leads to additional emissions of hazardous substances for the wildlife. In uST, this problem is solved thanks to the use of steel wheels of special design, which makes them more wear-resistant, for example, in comparison with railway wheel pairs.

Noise and vibration from string transport is significantly lower than from a railway, tram or monorail. It has already been studied that, for example, in the Moscow metro, the passenger is only safe for the first three seconds. Further on, negative factors will begin to affect the human body – an isolated and compressed space, as well as the strongest noise and vibration. uST transport does not contribute even a small fraction of that noise load.

The location of the string rail track structure above the ground does not prevent the movement of ground and surface water, the movement of people and animals, as well as agricultural and other machinery. The string route does not disturb the terrain, preserves the fertile soil, landscape and biodiversity of the surrounding area due to the minimum land allocation. Maintenance of the track structure does not require de-icing salts that are hazardous to the environment and the human body.

Ecologically clean string rail roads have point supports on the ground. This advantage, with the widespread use of transport and infrastructure complexes, can save vast territories for land users, which would otherwise be occupied by traditional transport communications, as soils under roads and railroads equal in area to five areas of Great Britain have already been destroyed on the planet. Vegetation will remain on these areas, annually replenishing the atmosphere with millions of tons of life-giving oxygen. The severity of the environmental pollution problem will then be significantly reduced to a safe degree