Advanced Rail Vehicle Positioning and Monitoring System: An Innovation by UST Inc.

The safe movement of unmanned vehicles depends on the accuracy of determining their position on the highway. UST Inc.’s specialists have developed and implemented a positioning system that can determine the location of uPods with an accuracy of up to 5 cm. We will explain how these indicators were achieved in our material.

Multi-level positioning architecture

In modern transportation management, the ability to determine the position of the vehicle quickly and accurately is a key aspect. Our engineers implemented comprehensive technology integrating several independent data channels: The GPS system, RFID tags, and dual-channel odometry.

RFID tags and magnets are attached to the supports of the uST complex. A reader is installed in each uPod. The integration of three technologies—GPS, RFID systems, and odometry—allows for the systematic control of the vehicle movements.

The system's algorithms ensure continuous data processing. They capture even the slightest deviation from normative trajectory and speed indicators.

Continuous monitoring of the track structure state

In addition to controlling travel, the system monitors the technical state of the overpass. It automatically creates a digital load model for each section, tracks vehicle passage, and collects operational statistics.

This data is used to generate monthly reports that identify areas with increased wear and tear. These reports allow to promptly take measures to rehabilitate or reinforce the structure, thereby reducing risks and increasing the track structure's overall reliability.

Video surveillance in 24/7 mode

The integrated video surveillance module is part of the automated control system that manages the uST complex. High-resolution cameras are placed on supports, stations, and other important points along the route. This creates a continuous digital field of view without blind spots.

The operator receives instant synchronization of visual information with the vehicle's exact coordinates, enabling an immediate response to any operational anomalies.

Reliability and MTBF

Two years of operation have confirmed the effectiveness of the innovative solution. During this period, the positioning system demonstrated high reliability, with a mean time between failures (MTBF) of 10,000 km. In the future, UST Inc.’s specialists intend to increase this figure to 50,000 kilometers.

More news

News

4 May 2023

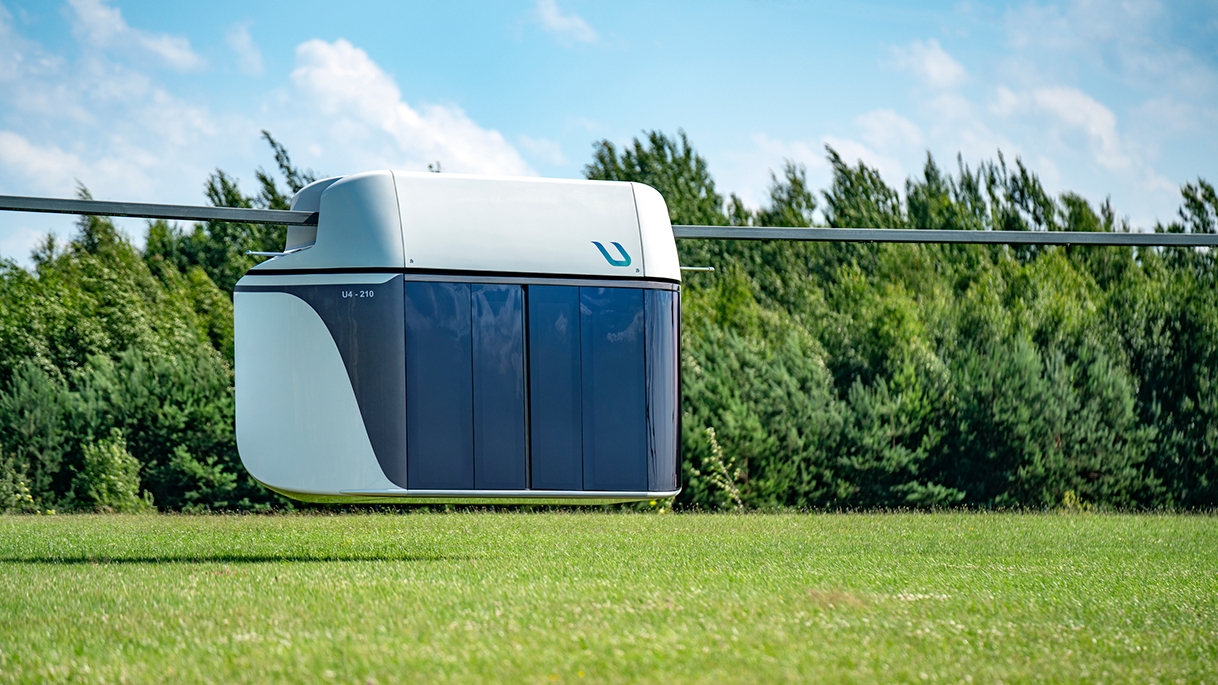

UST Inc. Has Presented a Solution to Optimize the Aerodynamics of uPods

World of Transport and Transportation scientific journal has published an article on improving the aerodynamic shape of uPods. A suspended monorail uBus was taken as a basis for the calculations. General Designer of UST Inc. Anatoli Unitsky is among the authors of the material.

News

20 January 2021

UAE Government Ministers and Saudi Arabian Business Representatives Visited uSky Center in Sharjah

UST Inc.'s R&D Center at Sharjah Research Technology and Innovation Park (SRTIP) was visited by official delegations from the UAE government and Saudi Arabian businessmen announcing plans in 2021 to build an innovative transportation system “the Line” as part of NEOM Linear City Project.

Opinion

4 April 2022

British Media Railway Technology Highlights the Advantages of String Transport

The publication describes how the transport from Unitsky String Technologies Inc. is capable to improve urban and suburban logistics.