Unload the Far Eastern ports: what uST complexes are capable of

UST Inc. continues the series of publications “Efficient Solution,” which talks about the advantages of the company’s technology. In this article we will look at how the implementation of uST complexes will help to cope with the increasing load on the port infrastructure on the Far East.

Port capacities cannot keep up with cargo turnover

Cargo shipping is carried out in compliance with port call schedules. The period of stay of ships and containers that are in transit and in port, the dates and times of loading and unloading are calculated thoroughly. Ship demurrage or late container return brings losses to both the owners, senders, and recipients of the cargo. As a whole, these are common problems.

Thus, in the largest universal port of the Far Eastern region - Vladivostok - there have been problems with terminal congestion for the past three years. In 2020–2022, the period for transshipment of containers from sea to rail transport could reach up to three weeks.

The problems of port infrastructure are widely discussed in Russia. At the end of March, the VIII Forum “The Port Infrastructure: Construction, Modernization, Operation” was held at the Moscow Analytical Center under the Government of the Russian Federation. It highlighted a number of issues, including the provision of the port with accompanying transport infrastructure, the absence of connection between the port infrastructure and the railway, the lack of new berths, container platforms, cranes for unloading containers and other equipment.

These are serious challenges in light of the fact that Russia expects to increase trade turnover with China up to $200 billion and with Turkey up to $100 billion in the coming years. At the same time, there is a disproportion in infrastructure development: the country has a large number of port terminals with a total capacity of 350 million tons, while the railway capacity is only 100 million tons. In this situation, alternative solutions are needed, such as those offered by UST Inc.

Almost three billion rubles per kilometer

Roads are vital for transporting ever-increasing amounts of cargo from ports. However, the construction of roads and the laying of railways in the Far East is a very expensive undertaking, which is not always within the budget.

For example, Accounts Chamber of the Russian Federation suggested the Primorye authorities to refuse the continuation of Vladivostok – Nakhodka – Vostochny port highway construction. The reasons were the rough terrain and the high cost of work: 309 billion Russian rubles, or 2.8 billion rubles per 1 kilometer of the route.

According to the scheme, the route crosses 112 watercourses (rivers, streams, canals), which will require the construction of at least 112 artificial structures.

Road work in the Far East is complicated by several factors. Firstly, there is a strong temperature difference, when in winter the thermometer drops to -40... -45 °C, and in summer it rises to +50 °C. Secondly, there is a layer of permafrost, rocks that contain ice. With warming, it begins to melt, and in winter it begins to grow, which causes deformation of the road surface.

The construction of bridges is also time-consuming and expensive. The ground is unstable, and in places where blind hyporheic tabetisols are developed, it is necessary to know their characteristics and permafrost parameters. And if it is a large river, like Lena, then it is also necessary to consider underflows and load peculiarities on the supporting structures of the ice drift during the period when the river breaks up.

No mooring space required, can be built on any ground

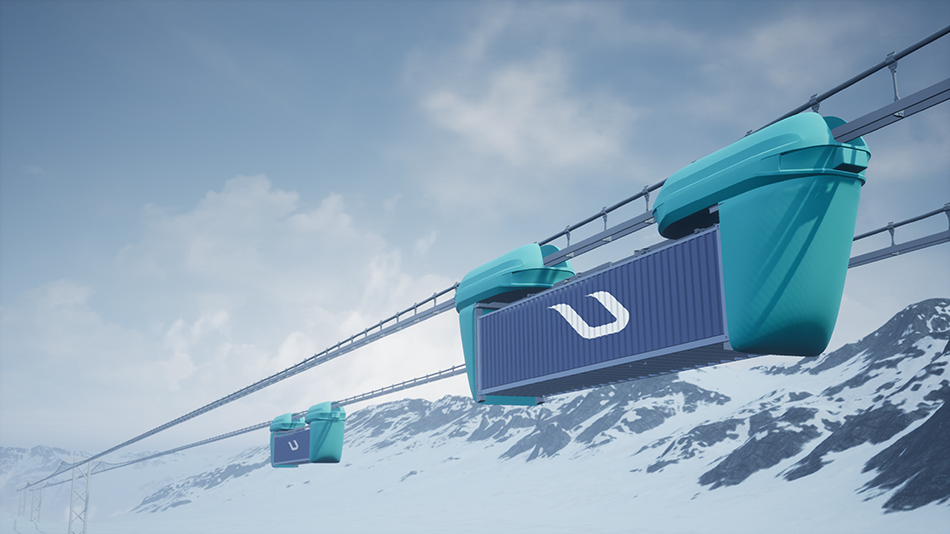

UST Inc. has developed technologies to solve all the above-mentioned problems. uST complexes can act as a link between the port and logistics hubs, and uPort can significantly increase the efficiency of marine terminals.

In the first case, unique solutions are used to build a string rail overpass in permafrost conditions. One of them is the use of closed-loop piles, which ensures the flow of cold into the pile in winter, that is, the negative temperature of the surrounding soils is even more reduced and the flow of heat into the base of the supports is blocked in summer.

In this way, it is possible to prevent the thawing of permafrost soils contacting with the foundation in summer and their frost heaving in winter.

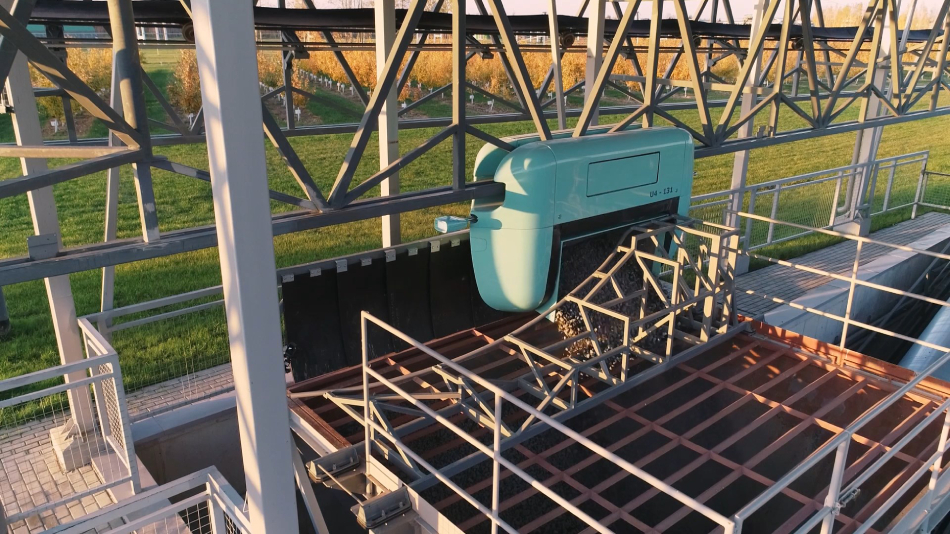

The route of the uST transport and infrastructure complex is laid above the ground at a height of about 6 meters, that eliminates the costly laying of the road surface and allows it not to depend on the terrain.

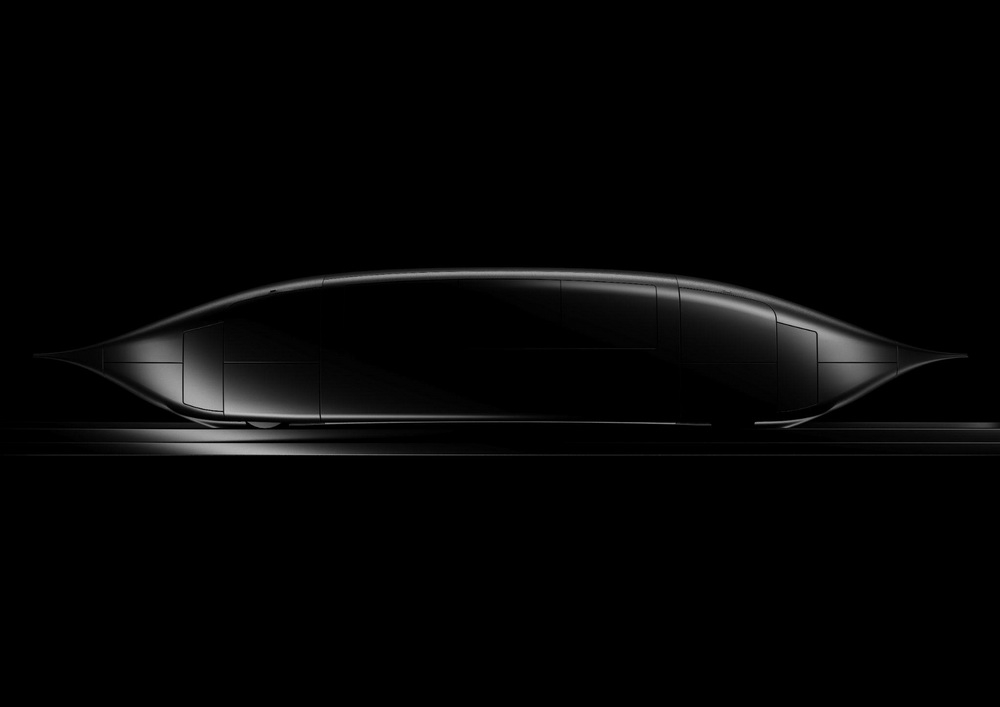

Electric vehicles on steel wheels move along the string rail overpass at speeds of up to 150 kilometers per hour, that significantly reduces the time of transportation of bulk, container, or liquid cargo to or from the port.

Snow and ice, unlike traditional bridges, overpasses and roads, do not accumulate on a narrow (less than 10 centimeters wide) string rail, since the track structure cleans itself of snow and ice every time the steel wheel of a rail electric vehicle passes.

To protect against corrosion, a factory protective zinc coating is applied to the pre-stressed wires of the reinforcing ropes in string rails. Special two-stage protection from the external environment is also provided.

The overpass, supporting structures, stations and rolling stock of the complex are designed for wind loads of up to 250 kilometers per hour.

Thanks to all the above, as well as the automated control system of uPod, the uST transport and infrastructure complex can be operated around the clock in any weather and season, even during the polar night.

A special uPort complex, which is being built directly on the sea shelf, further increases the speed of sea terminal’s operation. This does not require the construction of quay walls, which means dredging, and strengthening the shore. This allows ships not only to moor comfortably, but also to preserve the coastal ecosystem.

The introduction of uPort complexes also solves the problem of the lack of deep-sea ports in which large-sized dry cargo ships could be loaded/unloaded.

Reduce logistics costs and unlock transport potential

uST complexes are distinguished by a long service life: 25 years for rolling stock, 50 years for the track. Moreover, the operation of the complex does not depend on natural and climatic factors. For comparison: a highway built in permafrost conditions lasts up to 12 years and requires expensive maintenance every year.

To ensure the operation of the complexes, a small number of employees are required - management is automated, that significantly reduces the influence of the human factor and cuts down on personnel costs.

The implementation of uST complexes will significantly reduce the costs for road and port infrastructure development in the Far East.

More news

News

15 July 2025

Engineers' Diaries: How Intelligent Control of the uPod Works

A software engineer with international experience talks about the uPod, explaining the design of its machine vision and satellite navigation, and introducing the key components and principles of unmanned operation.

Interviews

15 December 2021

UST 2021: General Design Engineer of High-Speed Transport Complex Shared the Company’s Achievements

We spoke to Chief Structural Design Engineer of High-Speed Transport Complex Aliaksandr Kryvitski to learn what results have already been achieved.

News

21 January 2026

A Lecture Hall Dedicated to String Transport Technologies Opens at One of Kuzbass’ Leading Universities

The room was created with the aim of promoting uST solutions in a region with high potential for their implementation.