UST 2021: the Head of the Transport Overpass Department Shared the Company's Achievements

Yuri Kashchuk, head of the transport overpass department, spoke about the results of the last year and plans for the current one in the next round of interviews.

What does the Transport Overpass Department do?

Our subdivision works on designing the string-rail overpass. In addition, we are in charge of infrastructure facilities – turnout switches, transborders, as well as equipment that ensures the operation of the transport complex as a whole. This includes car washes, repair equipment, chargers, equipment of depots and maintenance areas, etc. Our team performs a full development cycle – from technical proposals to operational documentation.

Please tell us about the advantages of the overpass that you are designing?

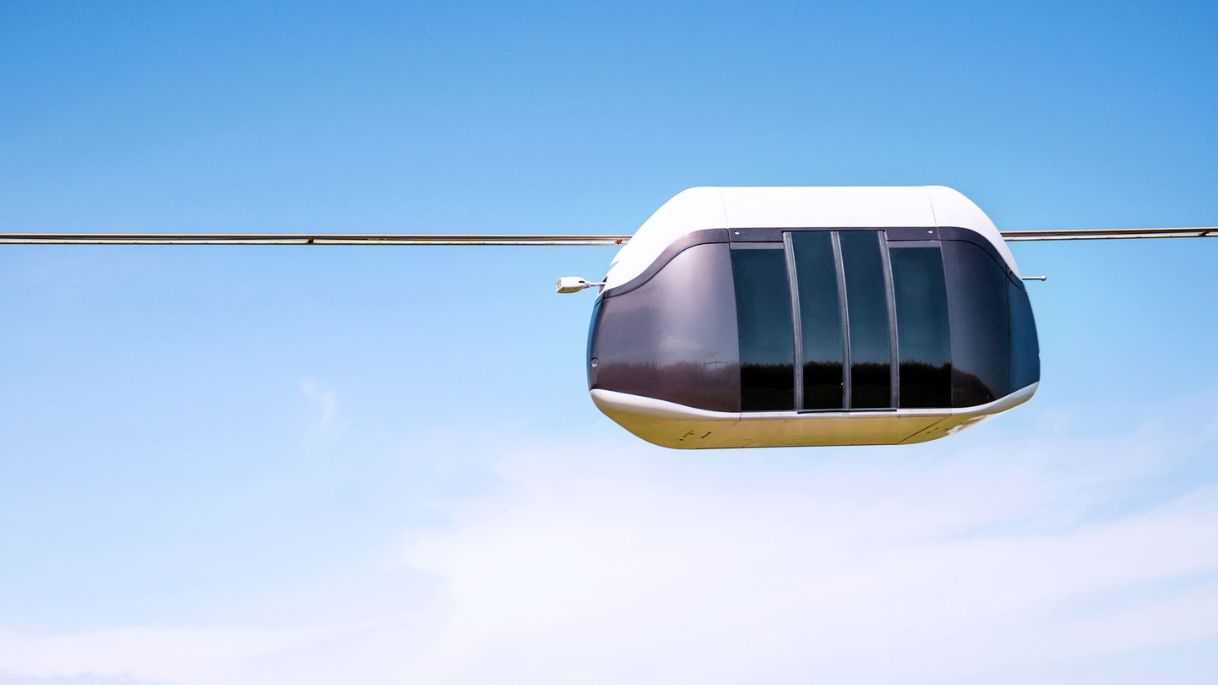

First of all, such structure allows to ensure high evenness and strength of the track. The main horizontal load from stretching falls on anchor supports. Intermediate supports take on the vertical load. They differ by an order of magnitude by less material consumption compared to similar elements in traditional overpasses. The track structure as a whole is distinguished by visual lightness and elegance, does not block the sky and makes it possible to preserve natural landscapes on the route of laying tracks. In addition, the cost of construction and operation is significantly lower than that of the existing transport solutions.

What difficulties did your Department face in 2021?

First of all, these are the circumstances related to the pandemic and the lockdowns. There are also breaks in ties with suppliers and manufacturers, and even failures of commitments. In fact, we worked under the conditions of the financial crisis. And despite this, we managed to do a lot.

Please tell us about the most significant results of the work.

We have developed several types of track structures. They will be implemented in EcoTechnoPark and the uSky Center in Sharjah. Work has already begun on manufacturing a semi-rigid track structure and supports in the UAE. These works are provided with special construction and installation equipment, which is manufactured according to our project. An uncut track structure with a length of more than two kilometers and a total weight of almost 1000 tons will be lifted from the ground to a height of more than 10 meters. This is the case when we will arrange the installation of a pre-stressed structure at the intersection of an existing highway for the first time in the world.

At the same time, the production of elements of the track structure for the commercial project "Unilite" is nearing completion in Belarus. Everything will be ready soon to start the installation.

According to the results of operating the "sagging track" in EcoTechnoPark, modernization was carried out this spring. We have refined the calculation methods for designing the units of connecting the track to supporting structures. Based on this and the experience of driving our electric rail vehicles, we have developed new parts – a "Сable-stayed girder", the so-called "Saddle". This improved the smoothness and comfort of passing intermediate supports.

Could you tell more about the tests that were carried out?

Our Department has conducted numerous tests to determine the possibility of using polymer materials and aluminum alloys in the track structure. Today, work continues on the use of various new progressive solutions as string elements. To do this, we have designed prototypes of attachment units on anchor supports, carried out resource tests and checks of the features declared by manufacturers. Based on this work, recommendations were drawn up for designers, the solutions taken for designing of track and infrastructure facilities were clarified and optimized.

As a result, we have developed a stand to test the solutions that should allow us to pass turnout passages without reducing the speed. Today, work is underway on its commissioning and preparation for direct operation.

I would like to add that our Department took an active part in the work on certification of transport complexes and preparation of regulatory documents to ensure their safety.

More news

News

31 May 2022

Unitsky String Technologies Inc. Hosted a Technical Meeting With the General Designer

The meeting took place in the head office of UST Inc. The designers discussed a range of matters, including the operation of string rail overpass under high temperatures.

Opinion

31 January 2022

Unitsky String Technologies Inc. Took the Stage in Agenzia Italia

The publication mentions that Unitsky String Technologies Inc. suggests passenger and cargo transportation, which could bridge the dessert in the UAE at record-breaking speeds.

Blog

28 March 2023

The Product of Unitsky String Technologies Inc. Is a Response to Challenges in the Transport Sector

Ten-point traffic jams paralyze huge cities. More than a million people perish in road accidents around the world every year. The problem of environmental pollution becomes more acute every day.