Increasing battery efficiency by 20%: UST Inc. engineers tested a ground heat accumulator

In today's world, energy efficiency has become a key focus in all sectors, from construction to industry. Heat preservation technologies are considered to be one of the most promising fields. The specialists at UST Inc. have created a laboratory prototype and a mathematical model of a ground thermal accumulator. The integration of the development into uST transport and infrastructure complexes opens up new opportunities for more environmentally friendly and cost-effective transportation solutions.

Integration into uST complexes

The ground thermal accumulator functions due to the ability of the soil to accumulate and store heat. There are pipes installed either in the ground or in a special container, where a heat-transfer fluid, such as water or antifreeze, flows. When there is an excess of heat, the system accumulates it and, if required, returns it for heating purposes.

uST complexes are suitable for implementing such solutions: vertical heat exchangers of ground accumulators can be installed inside the supports or other infrastructure components. The modular design, strength, and durability of the complexes make them ideal for integration with these storage devices. During the warmer seasons, the battery accumulates surplus heat, which is then utilized in the colder months for heating stations, technical spaces, or nearby structures.

Furthermore, these systems can be employed to warm up vehicle accumulators, enhancing their capacity by up to 15-20% in cold weather conditions. This helps to reduce operational costs and minimize the carbon footprint.

Features of the experimental setup

The laboratory sample includes a cylindrical container with a capacity of 180 liters, filled with sand. To reduce heat loss, the container is equipped with multi-layer thermal insulation. The side walls are covered in foil-faced foam, while the ends are clothed in plastic foam.

Heat exchange is carried out through a U-shaped tube that runs along the vertical axis of the battery. The heating is accomplished through the use of an electric boiler, which operates on two separate circulation loops.

To monitor the parameters throughout the entire battery, a network of 50 temperature sensors is installed on five different levels at varying distances from the heating element. This system enables you to closely observe the temperature distribution within the device.

Factors that influence the effectiveness

In the course of the experiments, the battery was subjected to a water-based heating, raising its temperature to +42 °C. This value is comparable to what can be achieved in practical situations without the need for supplementary heating. The engineers explored different cooling methods, both natural and forced, and examined heat dissipation at temperature variations ranging from +27 to +42 °C.

The key factors determining the battery performance were:

- Physical characteristics of the material used to create the battery

- Geometric characteristics (volume-to-surface ratio)

- Thermal insulation quality

- Characteristics of the heat-transfer fluid flows

- The duration of charging and discharging cycles

- Heat storage time

- Construction of heating elements

It also turned out that the effectiveness of the system depends on the depth of the groundwater. To maintain high productivity, it is important that the piles do not reach the water level.

Promising opportunities

The engineers at UST Inc. have developed and verified a mathematical model of the system. It will allow to perform computational simulations and adjust the battery parameters for different complexes.

Technologies for heat storage in the ground open up prospects for a significant restructuring of the energy system. The inclusion of these innovations in the uST transport infrastructure allows us to solve logistical problems and reduce financial costs and environmental impact compared to traditional modes of transport.

More news

News

4 May 2023

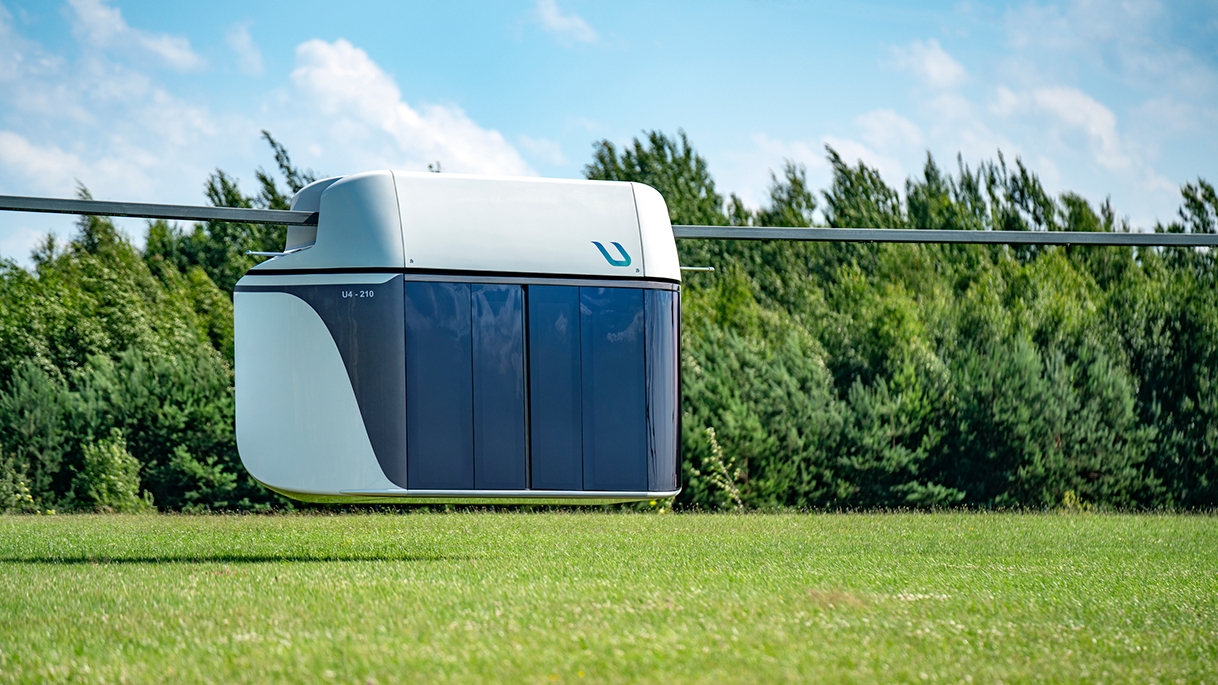

UST Inc. Has Presented a Solution to Optimize the Aerodynamics of uPods

World of Transport and Transportation scientific journal has published an article on improving the aerodynamic shape of uPods. A suspended monorail uBus was taken as a basis for the calculations. General Designer of UST Inc. Anatoli Unitsky is among the authors of the material.

News

13 October 2021

String Transport at GITEX Global: Anatoly Unitsky Presents His Program at the International Exhibition in Dubai

Anatoly Unitsky presents the string transport program at the international exhibition GITEX Global

Blog

5 December 2022

The uST Technology Is Considered as a Means of the Transport in the New Capital of Indonesia

UST Inc. continues to work on the application of the uST Technology in Indonesia within the framework of the agreement signed with ITS Indonesia. According to ITS Indonesia President William Sabandar, the company’s transportation and infrastructure complexes can be used in the future capital of Indonesia Nusantara.