The UST Transport Has a New Upgrade! We’re Sharing the Results

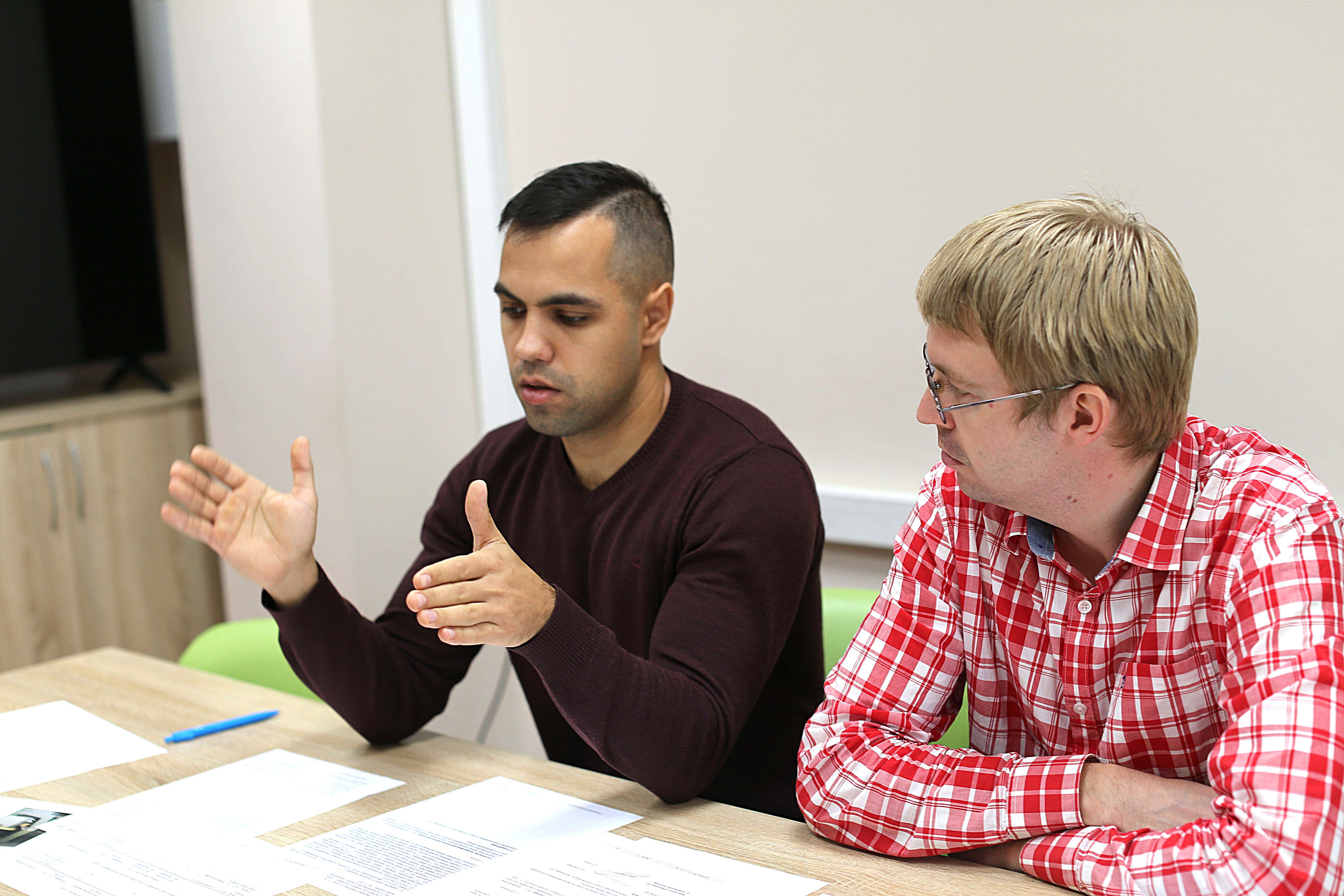

Unitsky String Technologies, Inc. is constantly looking for ways to optimize their transport solutions. This time the question is about pneumatic suspension. Vladimir Vyrvich, Design Engineer of the Chassis Design Office, and Ivan Romanenko, Head of the Configuration Design Office, spoke about the advantages the string transport gets after this component is installed.

Comfort comes first

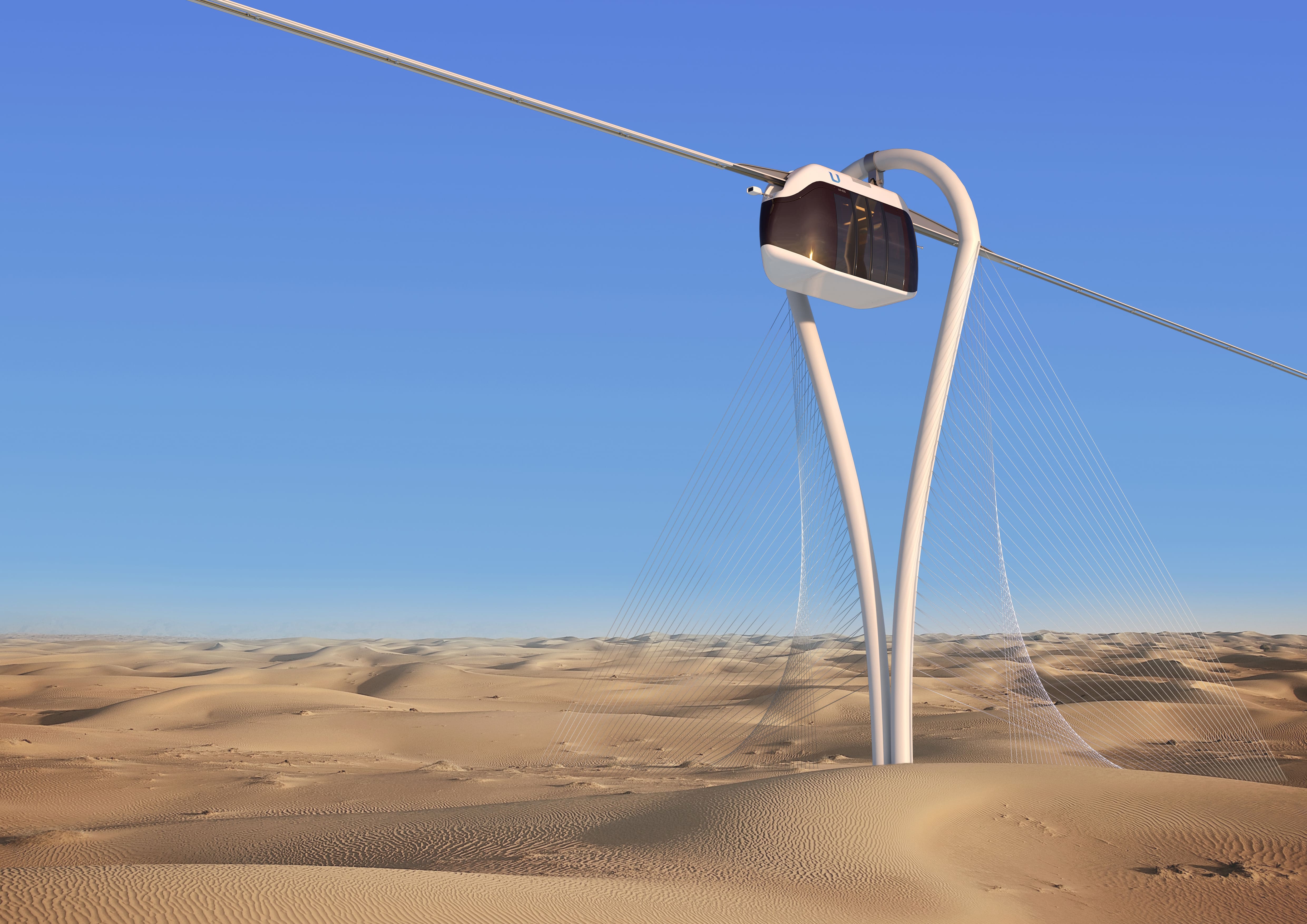

What was the task? The two unimobiles (uCar), which are run in EcoTechnoPark, were originally on a mechanical suspension. In this regard, there were small vibrations and noise in the cabin, which was transmitted through the wheels. These parameters were within normal limits. However, in order to make passenger comfort better, it was decided to improve the mechanical suspension by replacing it with the pneumatic one. Why the pneumatic? Because it had already been successfully implemented in other vehicles. For example, the pioneer is the uCont self-propelled chassis, which we sent to the United Arab Emirates. The pneumatic suspension, installed on it for the first time ever, showed positive results.

The main task was to implement pneumatic suspension into the operating vehicle without changing the entire car’s design. Using minimal modifications, we replaced the rigid buffer which was on a mechanical suspension, and installed the air cylinder of the same configuration, as well as laid the air tubes. One mounting bracket was introduced, since the task was to change the structure minimally. As we had large suspension travels, it was necessary to provide space inside the vehicle for the traction module movement. We had to increase the amount of plastic and modify the lower belt, which led to the slight increase in the vehicle’s size as well. In addition, we introduced a suspension level control system, which increased the amount of data and facilitated the transport telemetry analysis. For example, it became possible to monitor the level of the suspension position online.

What are the results?

Currently, we have ensured the ride comfort to be the same as in the business class car, and even better in terms of moving off-road, since the pneumatic suspension smooths out the unevenness of the track structure. It also reduced the noise load on passengers, thereby making transport safer compared with the metro. For example, it has already been studied a person could stay in the Moscow metro safely only for the first three seconds. After that the human body is badly affected because of an isolated and compressed space, as well as the strongest noise and vibration that are very harmful to people. In this regard, the UST transport is a perfect alternative. Another point is that today we can effectively use the carrying capacity of unicars and even allow overloading without losing driving qualities.

We’d like to add that pneumatic suspension is just one of the many string transport advantages. For example, the main strong point is the absence of traffic jams and other force majeures on the roads, that can lead to the emergency braking, which is also unsafe for passengers. That is because each unimobile (uPod), as well as the UST complexes as a whole, is equipped with its own intelligent control system. It continuously reads information about everything that happens on the track, as well as inside and around the cabin, analyzes this data and monitors the progress of the route assignment. This eliminates the human factor from transport management and ensures the highest level of traffic safety.

More news

Interviews

20 Junе 2025

The First Episode of “UST Inside”: Maksim Kubyshkin Speaks on the Future of Urban Transport

In the interview, the Deputy General Director for Designing at UST Inc. shared how emerging transportation technologies can transform the lives of millions.

Blog

12 September 2023

Zero Emissions: How Will uST Solutions Help to Accelerate the Transition to Eco-Friendly Transport?

uPods can become an efficient solution for the arrangement of urban passenger transportation. When traveling around the city and beyond, it is possible to save time if a second-level route is used instead of an electric car. In addition, there is no need to worry about an empty battery and the absence of a charging station.

Blog

6 February 2023

String-Rail Overpasses as an Alternative to Railways: What is the Advantage of the uST Solution?

The technologies developed by Unitsky String Technologies Inc. can be an efficient alternative to rail transport, intended, for example, for commercial transportation with established logistics.