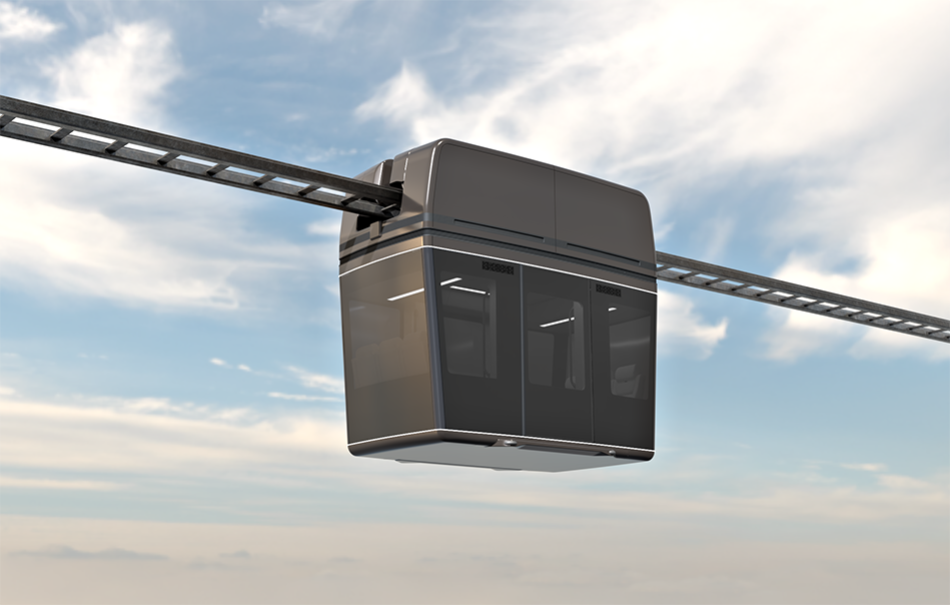

A Development for Testing the uPod Elements Is Presented in UST Inc.

The assembly of the self–propelled stand chassis of a bi-rail wheeled electric vehicle has been completed at the SW Plant production complex. There engineers will work out the design solutions and test the uST transport control systems. The model is already undergoing full-scale tests on a semi-rigid string rail overpass in EcoTechnoPark.

“Earlier, we had to test all the rolling stock elements directly in the uPods. This is rather inconvenient, as we could not always make demonstration runs or had to interrupt tests. In addition, testing any new solution required the vehicle components dismantling. To avoid this, we developed the self-propelled stand chassis. Its special modular design allows to carry out research and development work”, – said Ivan Romanenko, the Head of the Vehicle Layout Design Office.

The stand is a traction module and a weight-cargo model connected to each other. The model can be moved at a speed of 80 km/h. The stand capacity is 1000 kg. The rail electric vehicle is designed to provide easy access to parts and assemblies for easy maintenance.

The engineers of UST Inc. have paid special attention to automation. Sensors located in the model transmit measurement information to the control system. It, in turn, provides real-time data monitoring and analysis. This helps to determine the stand’s performance and prevent any problems. In this case, the operator can gain access to the control of the rail electric vehicle at any time.

The stand is equipped with a motion data recording system. It allows tracing all the events that occurred during the ride. The control algorithms are designed in such a way that no single failure will prevent a rail electric vehicle from moving independently.

Today, the specialists of UST Inc. are conducting the configuration and adjustment of new control algorithms. Full operation of the stand will begin after successful commissioning. The first tests will be on the automatic steering system that maintains straight-line movement or driving in a turn. All solutions that successfully pass the tests will be incorporated into new uST transport projects.

More news

The commercial projects

4 September 2025

Only seating and high security: What kind of uPod would be best for the Sosny Sanatorium?

Recently, the specifics of the technical requirements for a uPod designed for transporting vacationers have been revealed.

News

22 May 2024

The uST Solution Is Being Considered for Integration With Seaports

DP World is interested in employing the uST Solution in maritime transportation.

Blog

18 November 2020

Why Is Unitsky String Technologies Inc. Transport Complex Unique? Episode 5

You will get to know the following from the next release of the cyclus about the Unitsky String Technologies Inc. transport complex: how string transport will solve the problem of the “last mile” in large cities, what development shipping traffic will receive from the introduction of Unitsky’s invention in the sector, and how the transfer of energy “without loss” over huge distances is implemented in the technology.