Unitsky String Technologies Inc. Held a Technical Meeting on Safety of the Track Structures of the Transport Complex

Chaired by the General Designer Anatoli Unitsky, the design engineering team discussed safety matters of the string rail overpass of the uST transport and infrastructure complex.

The transport will become even more comfortable and reliable

The office is crowded, the large table is full of metal parts — the designers have gathered together to discuss the safety matters of the elements of the string rail overpass. Among them is the railhead (raceway). Low noise, smoothness, and safety of the vehicle depend on the assembly quality of this component.

The design team of the string rail overpass is working out a solution to the problem that will make uST transport even more comfortable and safe for passengers. To this end, the transport must travel on a solid raceway without rail joints.

UST Inc. reference

The height of the steel supporter has an impact on the lifetime of the railhead. Thus, original string rail track structures can remain operable for up to 100 years. Compare: roadbeds are replaced every 5-10 years and it’s 6-8 years for the rope in cableways.

Every detail matters as far as sustainability issues are concerned

The uST rail electric cars do not harm the nature. It is the same about the track structure of string transport. The raceway is electrified and the current is collected through the wheel. As a result, the efficiency goes up and the costs go down. Therefore, it has a positive impact on sustainability of the transport. We consume less energy that has to be produced with a negative impact on the environment.

The designers are working together to ensure good current conduction among all components of the track structure. The tracks are constructed using a polymer binder (current insulator), which requires developing a solution that will provide sufficient electrical contact to all parts of the headrail.

— We have carried out successful conductivity tests of the prototypes. They will compose the headrail. We will employ the most optimal variant in the track structures, — told Yury Kashchuk, the Head of Transport Overpass Department.

Efficient, light-weight and elegant track

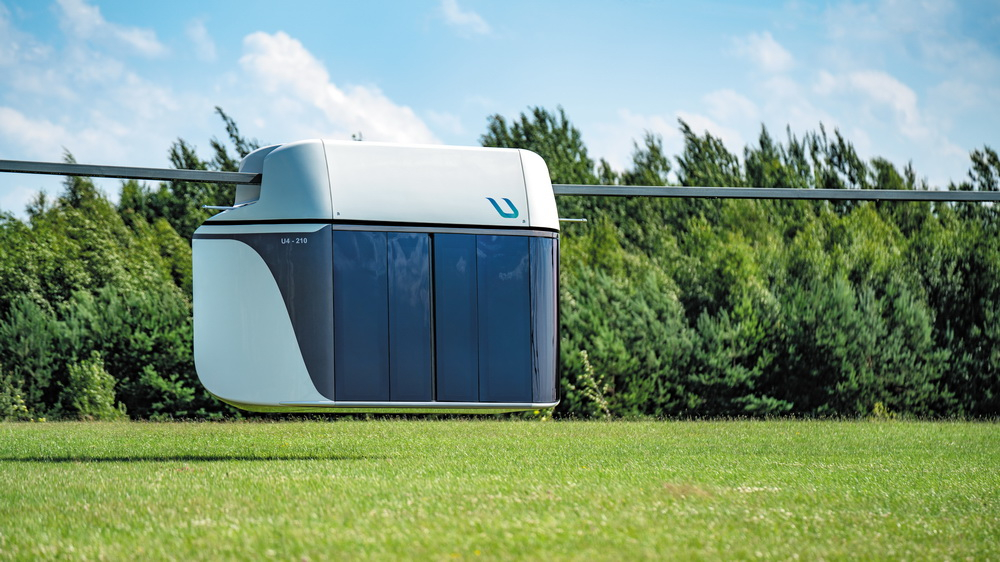

Recall that the uST track structure represents an innovative string rail. This is an uncut (lengthwise) steel, reinforced concrete, or steel reinforced beam or truss equipped with a rail head with additional reinforcement by pre-stretched strings.

Flat railhead and cylinder steel wheel ensure minimum energy consumption for the travel. Moreover, such a unique structure guarantees high evenness and strength of the track.

The primary horizontal stretching load is laid on the anchor support while the intermediate supports withstand the vertical load and consume much less materials compared to similar components in conventional overpasses.

Furthermore, the above characteristics of the uST track structure preserve natural landscapes along the layout of the track and make it look light and delicate.

More news

News

10 March 2022

Even the Phone Screen Withstood: uST Tested a Door Pinching

Not so long ago, we talked about a new development for electric string transport vehicles – a unique design of sliding doors, which was independently created by the engineers from Unitsky String Technologies Inc.

News

25 October 2022

Unitsky String Technologies Inc. Unveils New Website

User-friendly, informative and intuitive – the new website of UST Inc. is already available for users. The portal provides information about uST Transport & Infrastructure Complexes, the advantages of the technology and the company's activities.

News

5 December 2024

UST Inc. Received a New Certificate of Conformity

Unitsky String Technologies Inc. extended the certificate of conformity