There Are No Analogues: uST Develops a Unique Technique for the Selection of Adhesive Joints

The first stage of research work has begun in the company. Based on their results, a methodology that has no analogues in the world will be created. It will allow evaluating the strength of adhesive joints for transport and infrastructure complexes. See the details in the report from the uST laboratory.

Process engineer Alexander Karaban mixes special glue. Then he puts the container in the chamber, where air is pumped out with the help of a vacuum pump.

This will allow the adhesive to get rid of the entrained air and become more dense. Accordingly, the strength of the adhesive joint will increase, – explains Alexander.

After the air is pumped, he shows what happened to the glue: only a fifth of the total volume remained!

Then Alexander takes metal samples for testing, carefully lubricates them with prepared glue and connects. Two pieces of metal are held together tightly – it’s impossible to tear them apart. The glued samples are checked for compliance with geometric parameters and left to gain strength for at least two weeks, says the process engineer.

When all the samples are completely ready, the second stage begins: the strength of the adhesive joint will be checked in a tensile testing machine.

During the third stage, a computer mathematical model will be developed on the basis of research data. It will allow evaluating in electronic form whether a particular adhesive compound is able to work in the nodes of transport complexes. This technique will significantly save the company's resources and speed up the process of developing uST transport and infrastructure complexes.

Alexander Shibut, the head of the laboratory, said that such studies were almost never carried out anywhere. In fact, the company's process engineers are working on a unique project that has no analogues in the world.

Depending on the design of the element, the adhesive line has a different thickness. With a change in thickness, the strength and deformation properties of the adhesive joint change as well. In order to calculate the strength properties of the glued elements, you must have a clear idea of the strength of the glue itself. So, we launched a cycle of research.

Unitsky String Technologies Inc. actively uses advanced composite materials in the design and implementation of transport and infrastructure systems. Adhesives, compounds, structural plastics and other materials are what the lab works with.

When selecting glue, the company’s employees try to use materials from well-known world brands. For example, Henkel (Loctite), Scott Bader, 3M, Spolchemie, and others. This guarantees not only proven quality, but also the availability of all kinds of documents confirming compliance with the most stringent standards, which plays an important role in the subsequent certification of string transport.

The development of a unique program for the selection of adhesive joints is an important step that will speed up production processes and add to the innovative developments of the company.

More news

News

8 October 2020

The ISO 14001:2017 Environmental Certificate Has Been Extended

Unitsky String Technologies Inc. has passed a recertification audit of the environmental management system for compliance with the requirements of ISO 14001:2017 in the international conformity assessment system.

Blog

15 September 2021

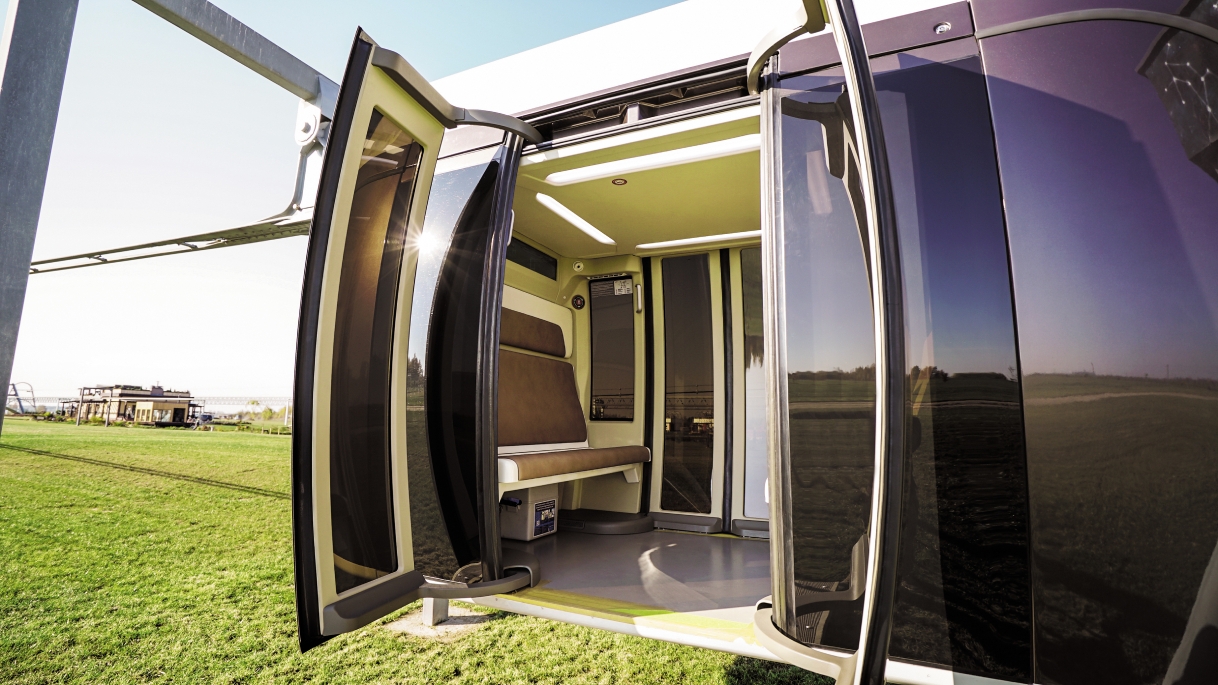

Is uCar Safe to Use? Yes!

As part of comprehensive tests of uSky Transport & Infrastructure Technology, TUV SW Standardization Certification has issued a Certificate of Conformity proving safety of tropical Unicar manufactured by Unitsky String Technologies Inc. (Minsk, Republic of Belarus) and designed for urban transportation.

Blog

6 March 2023

uST Transport and Infrastructure Complexes as a Solution to the Problem of Air Hubs Accessibility

The construction of uST transport and infrastructure complexes will ensure a fast and safe transfer to airports.