Методы защиты комплекса uST от стихийных бедствий

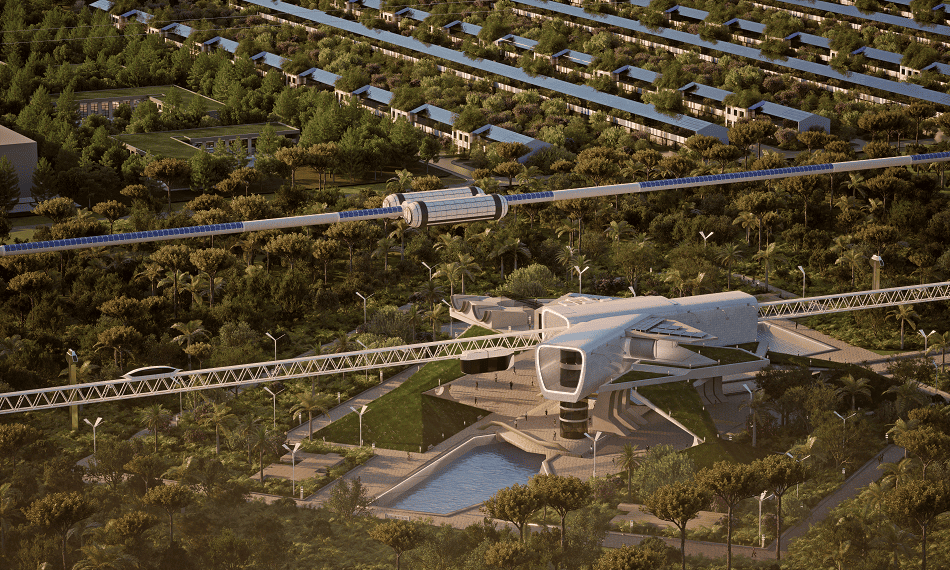

Одно из важнейших преимуществ транспортно-инфраструктурных комплексов uST – их пригодность для возведения даже на территориях со сложным рельефом. Такие локации нередко имеют не только особенности ландшафта, но и крайне неблагоприятные климатические условия. Песчаные бури, тропические дожди и грозы, сильные морозы или экстремальная жара – всё это факторы, которые необходимо учитывать на этапе проектирования и строительства. Важно, что комплексы uST спроектированы с учётом подобных нагрузок и обладают защитными механизмами, позволяющими эффективно противостоять самым разрушительным проявлениям природы.

Общий расчёт условий эксплуатации

Эстакады транспортно-инфраструктурного комплекса uST разработаны для эксплуатации в широком диапазоне температур: от -60 °C в условиях холодного климата до +55 °C – для тропиков. Это подтверждается действующими линиями практической реализации в ЭкоТехноПарке (Марьина Горка, Беларусь) и Центре uSky (Шарджа, ОАЭ). Напомним, нижний температурный предел в Беларуси может достигать -40 °C, тогда как в Эмиратах температура нередко поднимается до +50 °C и выше.

Важно отметить, что изменение характеристик рельсо-струнной путевой структуры при конкретном температурном воздействии сразу закладывается в проект для отдельно взятого региона. Это исключает ухудшение работоспособности комплексов uST на весь срок эксплуатации.

Такой результат удалось получить за счёт применения предварительно напряжённого рельса, конструкция которого исключает наличие сварных швов – наиболее уязвимых элементов традиционных железобетонных изделий. Благодаря этому ресурс прочности струнных конструкций сохраняется даже при экстремальных условиях: теоретический предел их работоспособности достигается лишь при охлаждении до температуры жидкого азота, около -200 °C, что в природных условиях практически невозможно.

Испытания на устойчивость

Температурные деформации, динамическое и атмосферное воздействие – основные нагрузки, которым рельсо-струнные эстакады uST подвергаются постоянно. Учитывая сложности маршрутов, для которых они предназначены, инженеры и проектировщики добились максимально долгой безремонтной эксплуатации всех элементов комплекса uST.

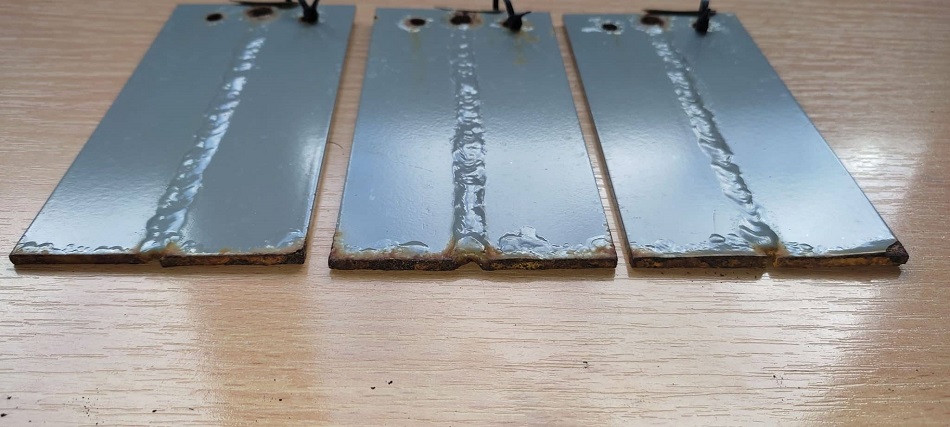

Для этого все материалы, из которых строится рельсо-струнная эстакада, проходят испытания на устойчивость в лабораториях, где создаются климатические условия регионов, в которых будут эксплуатироваться системы uST.

В особых камерах создаётся циклическое воздействие на материалы – суточный срок испытаний в них сопоставим с несколькими месяцами работы в естественной среде. Так, в камере искусственного солнца проверяется устойчивость материалов в жарком климате, в камере холода – воздействие сибирских морозов. При обработке соляным туманом воспроизводятся условия морских побережий, а в камере влажности – тропических ливней. В итоге инженеры выбирают лишь те материалы, которые показали себя устойчивее других. Затем на основе математической модели рассчитывается их предельный срок эксплуатации.

Допустимая нагрузка

В настоящий момент комплексы uST полностью адаптированы к применению во всех климатических зонах, пригодных для проживания человека. Причём речь идёт обо всех составляющих комплекса, в том числе о юнимобилях. Так, системы uST отлично выдерживают нагрузки в условиях влажного тропического климата, где сезонные осадки могут выпадать в количестве 2–3 мм/мин, а влажность достигает 100 %.

Ветроустойчивость для работы стандартного комплекса uST составляет 90 км/ч, или 25 м/с. Специальные варианты рельсо-струнных транспортных систем могут выдержать нагрузки до 250 км/ч, или 70 м/с, – эти показатели характерны для шквалистых порывов ветра и даже смерчей.

Также транспортные системы uST прекрасно выдерживают постоянное воздействие песчаных бурь. Например, комплекс «Карат» успешно эксплуатируется в ОАЭ. За это время не было зафиксировано ни одного перебоя как в работе тягового электропривода, так и в основных системах. Этого инженерам компании удалось добиться за счёт таких решений, как развитая система фильтрации, устройство очистки поверхности качения рельса от налипшего песка, система продувки тягового модуля и система его охлаждения с независимыми контурами.

Экстремальная нагрузка

В некоторых регионах нашей планеты погода настолько сурова, что может превратиться в стихийное бедствие. Но даже в этом случае комплексы uST будут продолжать работать. Как мы уже сказали, струнный рельс, по которому движутся юнимобили, отличается высокой прочностью. Благодаря технологии преднапряжения вся горизонтальная нагрузка распределяется на анкерные опоры, а вертикальная нагрузка – на промежуточные опоры. Первые изготовлены из монолитного бетона, вторые – из стальных труб с оттяжками. А крепление верха опоры (опорное седло) к путевой структуре восьмикратно увеличивает её несущую способность.

При проектировании эстакады на сейсмически нестабильных территориях, а также в местах, подверженных затоплению или ураганам, учитываются все риски, связанные с экстремальными воздействиями на опорные конструкции. Высокопрочные фундаменты анкерных опор даже при затяжных катаклизмах обеспечивают устойчивость надземной эстакады. Согласно экспертному анализу, конструкции гарантируют безопасную работу даже при землетрясении в 9 баллов по шкале Рихтера.

Что касается удара молнии во время ливня или урагана, то и здесь в юнимобилях предусмотрен широкий комплекс мер для обеспечения безопасности транспорта и пассажиров. Так, конструкторское бюро UST Inc. защитило все участки электроцепи от токов короткого замыкания комплекса. Ограничитель перенапряжений оградит юнимобиль от вторичного воздействия молнии.

При этом вся проводка струнного транспорта не содержит галогены в своём составе, что снижает её горючесть и токсичность в случае тления. Всё оборудование размещено в герметичных металлических пожароустойчивых отсеках. Системы безопасности транспорта дополнены функцией автоматического пожаротушения и тепловыми извещателями, а в местах выхода жгутов из шкафа предусмотрены огневые барьеры.

Универсальное решение

Рельсо-струнный комплекс uST спроектирован для эксплуатации с перепадом температур на 120 °C: от -60 до +60 °C. Он устойчив к снежным заносам высотой до 10 м благодаря путевой структуре, проложенной на высоте не ниже 15 м. Этот транспорт невосприимчив к обледенению, песчаным бурям, наводнениям и цунами высотой до 10 м, проливным дождям и туманам, штормовому ветру и землетрясениям. Безремонтная эксплуатация комплекса uST возможна в течение минимум 50 лет при круглогодичной работе юнимобилей.

Читайте также

Новости

4 июня 2025 г.

Рубеж в 120 км/ч взят: в Центре uSky проведены успешные испытания «Карата»

Юнибус «Карат» U4-212 во время демонстрационных заездов показал высокий уровень комфорта – оценки были в пределах «очень хорошо» и «отлично».

Интервью

28 августа 2020 г.

Интервью с начальником отдела IT-сопровождения

Начальник отдела IT-сопровождения Алексей Шкода удивит вас объёмами цифровых данных, которыми ежедневно оперирует Unitsky String Technologies Inc., и поделится профессиональной тайной: каким набором навыков нужно обладать, чтобы бесперебойно поддерживать в рабочем состоянии колоссальную инфраструктуру огромной инжиниринговой компании.

Новости

3 сентября 2025 г.

Новый выпуск «UST Инсайд» с Сергеем Артюшевским

Интервью будет интересно всем, кто следит за развитием передовых транспортных технологий и ценит роль науки в индустрии.